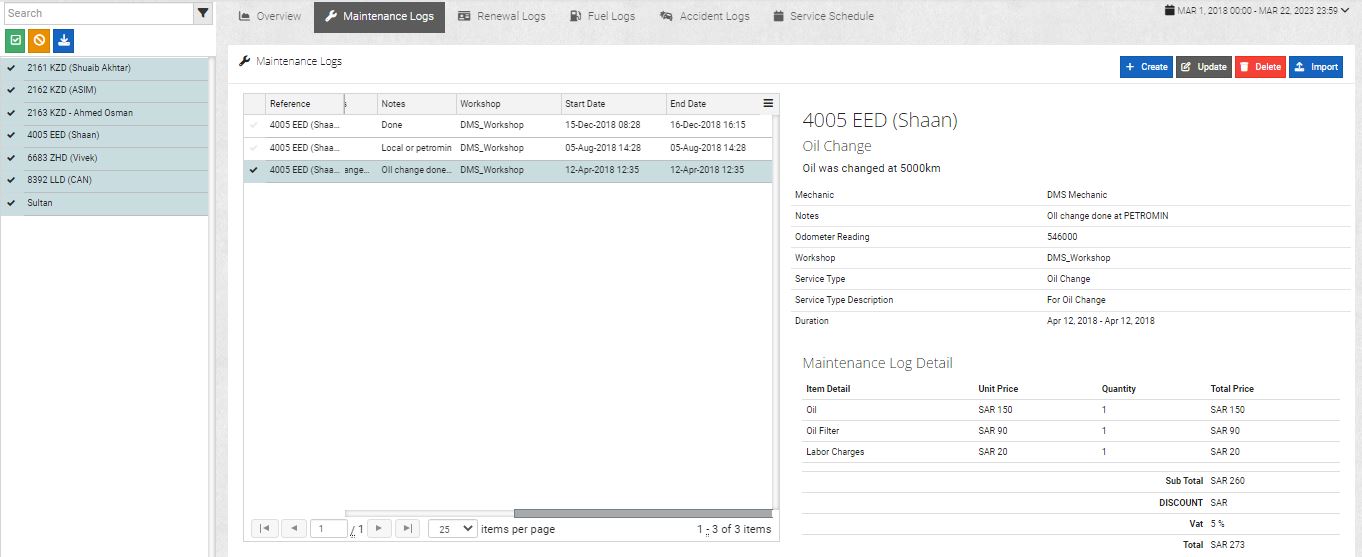

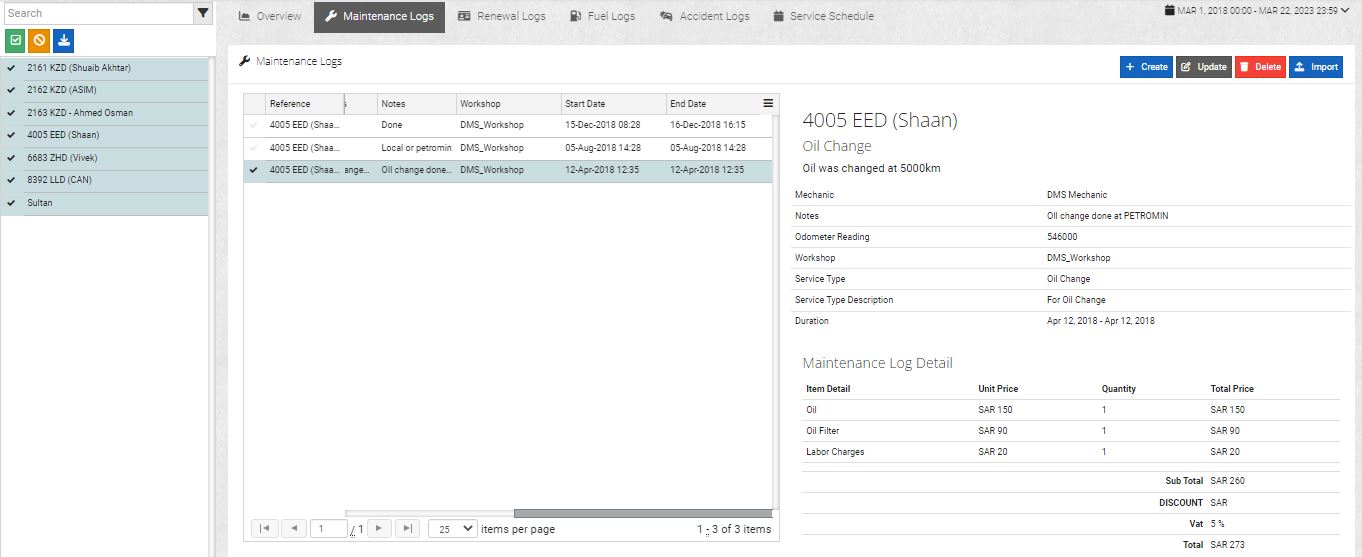

An upkeep fleet requires a solid, long-term preventative maintenance strategy that not only maximizes fleet uptime but also extends vehicle lifespan, keeping your fleet well-maintained to assure the safety of your assets while they are in motion.

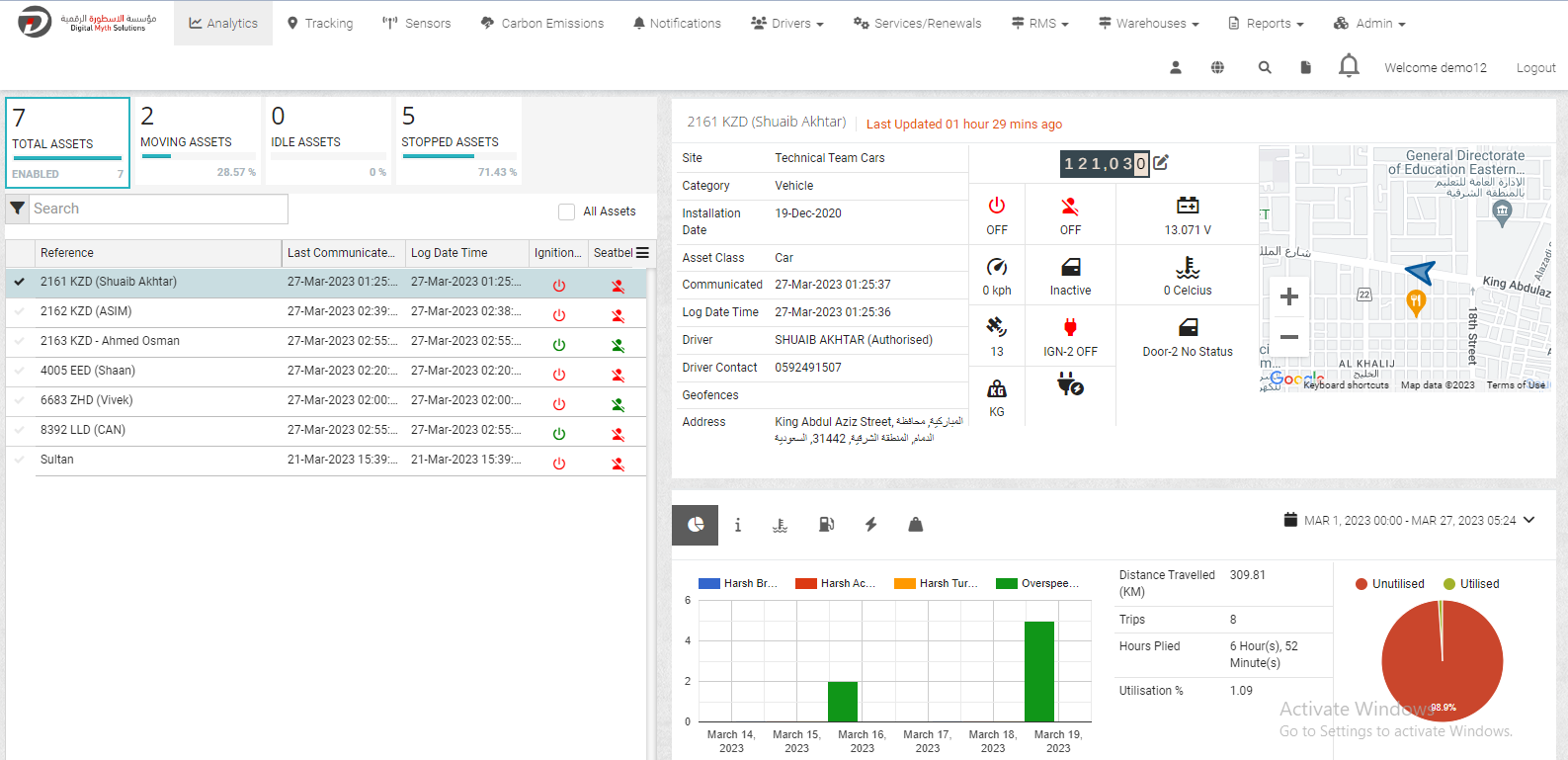

Without telematics, preventative maintenance can be complicated. Eagle-I provides a full spectrum approach to the maintenance of fleets. With the integration of OBD-II, a DTC or a Diagnostic Trouble Code, is generated to notify about vehicle engine’s issues. There are typically limits for each system within your vehicle. When the vehicle detects that the issue exceeds these limits, it sends out a trouble code. OBD data obtained from IoT sensors embedded in your fleet can later be analysed to decide which components should be changed before they break down or cause an accident. Besides this, root cause of most issues can also be diagnosed remotely.