Supply Chain

with Eagle-IoT

Empowering the supply chain industry with real-time visibility, data-driven decision-making, and automated asset management.

Why Choose Eagle-IoT for the Supply Chain Industry?

Eagle-IoT offers a comprehensive IoT solution tailored to address the complex challenges (from asset tracking to route optimization, delays, and operational inefficiencies ) faced by the supply chain industry. Our innovative platform provides real-time visibility, automation, and actionable insights to streamline operations, optimize warehouses & asset management, and enhance overall efficiency. By leveraging Eagle-IoT, businesses can gain a competitive edge through improved asset tracking, route optimization, and reduced operational inefficiencies.

Route Optimization

Enhanced Security Features

Cold Chain Monitoring

Data-Driven Insights

OBD Diagnostics

Scalable Solution

Waste Reduction

Industry Expertise

Revolutionize Your Supply Chain Operations with Eagle-IoT

Solutions for Supply chain industry

route Optimization

route Optimization

Eagle-IoT helps you reduce fuel costs and delivery times by optimizing routes for your fleet. Our algorithms consider real-time traffic, weather, and other variables to create the most efficient route plans for your delivery vehicles.

- Dynamic route suggestions based on traffic data

- Driver navigation integration

Geofences and Location Alerts

Geofences and Location Alerts

Define virtual boundaries (Geofences) for critical zones such as distributiongeofences centers, loading docks, or high-security areas. Receive instant alerts when assets or vehicles enter or exit these zones, ensuring tighter control over asset movements and security.

- Multiple geofence setup (polygon, circular, rectangular zones)

- Entry/exit notifications via email, SMS, or app alerts

- Color-coded geofences for easy identification

Warehouse Monitoring

Warehouse Monitoring

Monitor and manage your inventory and warehouse conditions with IoT-enabled sensors for temperature, humidity, and stock levels. Ensure that your products, especially perishables, are stored in optimal conditions to reduce spoilage and maintain compliance.

- Temperature and humidity tracking

- Automated alerts for unsafe conditions

- Compliance reporting for regulated goods

Cold Chain Monitoring

Cold Chain Monitoring

For supply chains dealing with temperature-sensitive products (like pharmaceuticals or perishables), Eagle-IoT offers cold chain monitoring solutions. Continuously track the temperature of your shipments, and receive immediate alerts if conditions deviate from safe ranges.

- Real-time temperature and humidity tracking

- Custom alerts for temperature breaches

- Compliance reports for audits and regulatory bodies

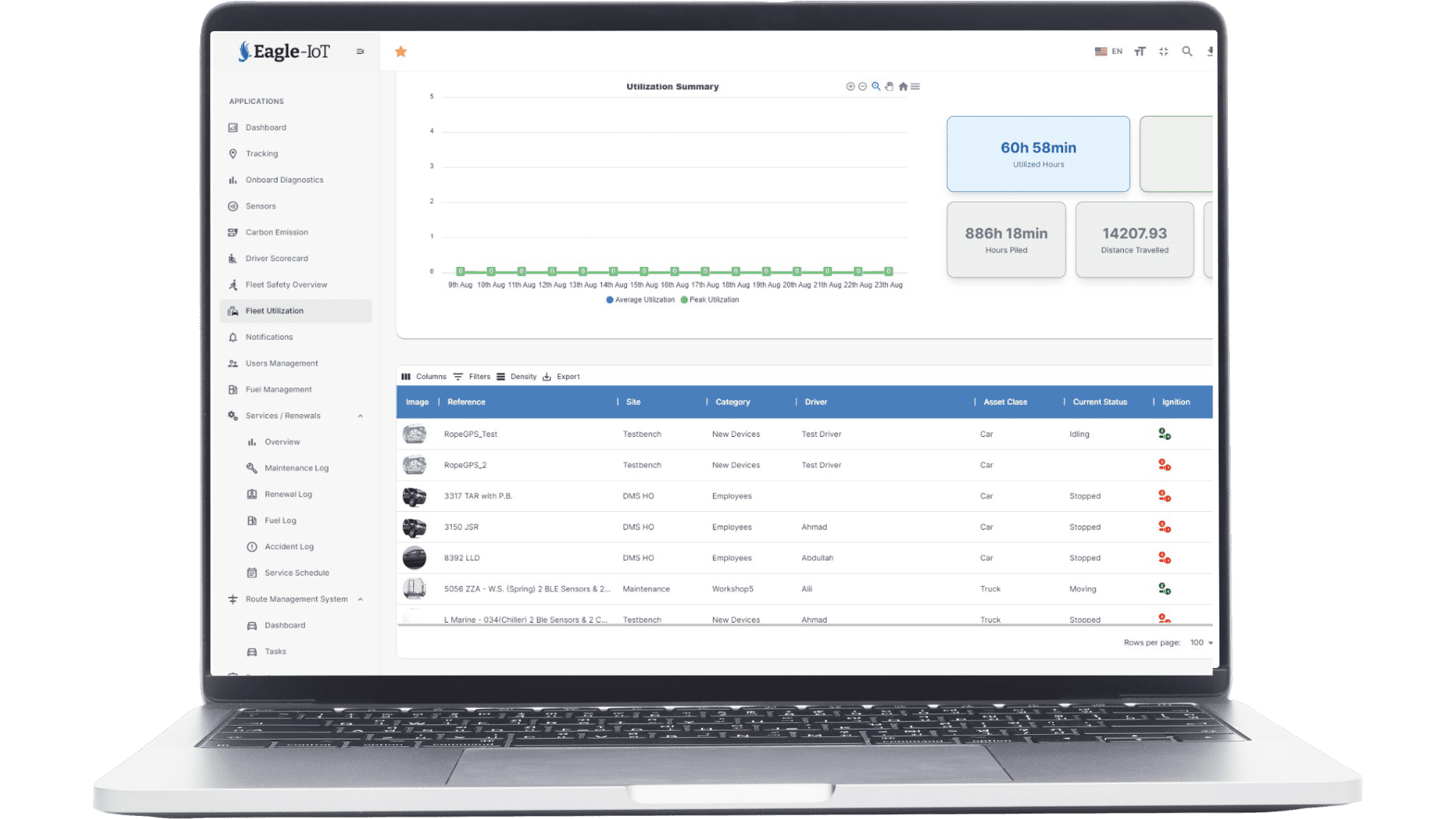

Supply Chain Analytics

Supply Chain Analytics

Utilize Eagle-IoT’s advanced analytics tools to gain detailed insights into every aspect of your supply chain. Analyze asset utilization, driver performance, inventory trends, and route efficiency to continuously improve operational outcomes.

- Customizable dashboards and reports

- Trend analysis for demand forecasting

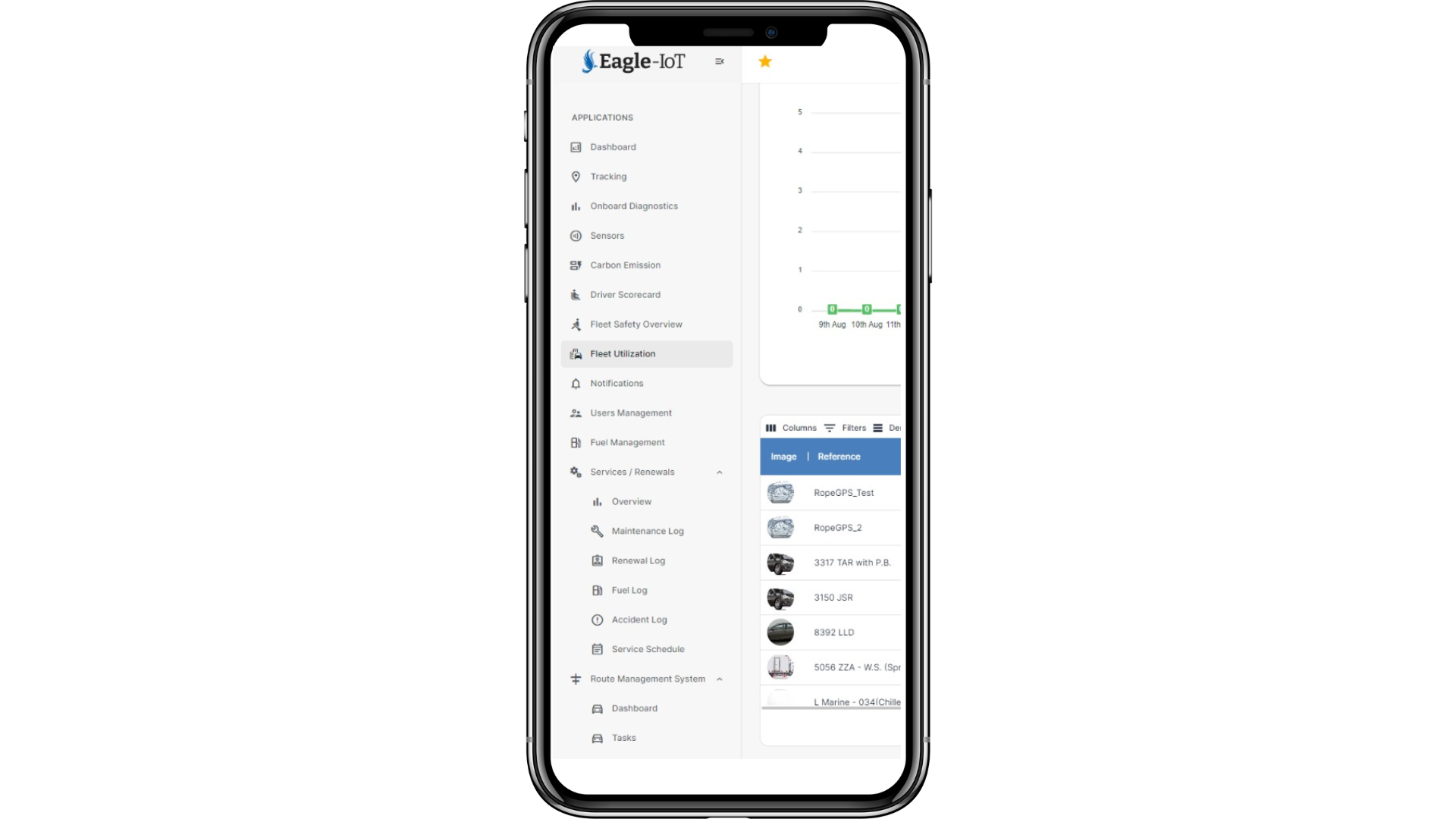

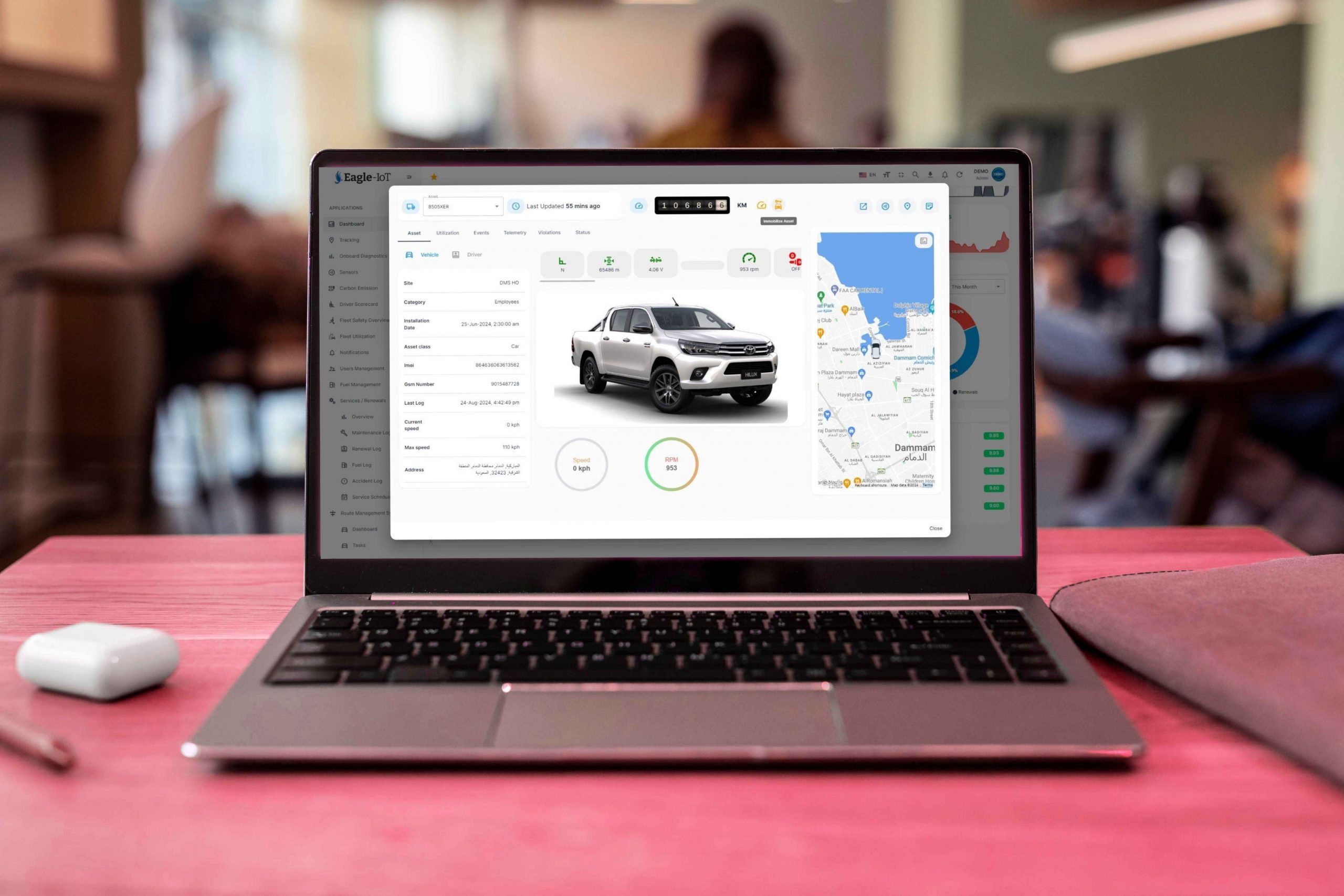

Fleet Management

Fleet Management

Manage your fleet more effectively with Eagle-IoT’s fleet management platform. Track your vehicles in real-time, monitor driver behavior, and automate vehicle maintenance to keep your fleet running smoothly.

- Driver scorecards and performance monitoring

- Preventive maintenance scheduling

- Fuel consumption analysis

Why Choose Our Solutions?

Enhanced Visibility

Gain full transparency over every asset and shipment throughout the entire supply chain. With real-time data and insights, you can address disruptions before they impact your business

Cost Efficiency

Reduce operational costs by optimizing resource allocation, minimizing fuel usage, and automating processes like route planning and preventive maintenance

Improved Compliance

Ensure regulatory compliance with Saudi Food and Drug Authority (SFDA) with our automated reporting and real-time monitoring of environmental factors like temperature and humidity in your warehouses or vehicles

Increased Security

Protect valuable assets and goods with geofencing, location-based alerts, and live notifications on unauthorized asset movements or suspicious activity

USE CASES

Logistics and Distribution

Real-time vehicle tracking, optimized routes, and driver behavior analysis ensure timely deliveries and efficient fleet utilization, resulting in reduced lead times and fuel costs.

Cold Chain and Pharmaceutical Logistics

Temperature-sensitive shipments are monitored throughout the supply chain to maintain compliance with stringent pharmaceutical and food safety regulations, mitigating spoilage and compliance risks.

Manufacturing Supply Chains

Monitoring the movement of raw materials and finished goods within the production process enhances efficiency and minimizes waste, leading to better resource allocation and reduced delays.

Frequently Asked Questions (FAQ)

What specific benefits does Eagle-IoT bring to the supply chain industry?

Eagle-IoT provides real-time tracking, route optimization, predictive maintenance, and advanced analytics that improve visibility, efficiency, and decision-making within supply chain operations. These features help reduce costs, prevent asset loss, enhance security, and optimize delivery routes, resulting in smoother, faster, and more reliable supply chain processes.

Can Eagle-IoT help improve our fleet’s fuel efficiency?

Yes, Eagle-IoT’s route optimization tools help reduce fuel consumption by suggesting the most efficient routes based on real-time data like traffic, weather, and road conditions. Additionally, fuel consumption monitoring and analysis can identify inefficiencies and reduce fuel costs.

How does Eagle-IoT support temperature-sensitive shipments?

For cold chain management, Eagle-IoT provides real-time temperature and humidity monitoring to ensure that sensitive goods, like food or pharmaceuticals, are stored and transported under the right conditions. Alerts can be set to notify managers if temperature thresholds are crossed, ensuring compliance and protecting goods from spoilage.

What is geofencing, and how can it benefit our supply chain?

Geofencing allows you to create virtual geographic boundaries around locations such as warehouses, distribution centers, or restricted areas. With Eagle-IoT, you’ll receive instant alerts when assets enter or leave these zones, helping you enhance security and keep track of inventory, vehicles, and shipments in real time.

Does Eagle-IoT provide route planning and navigation for drivers?

Yes, Eagle-IoT offers a powerful route planning feature that calculates the most efficient routes for drivers based on current conditions like traffic, road closures, and weather. You can also dispatch the nearest available vehicle for urgent deliveries and share detailed navigation information with drivers through our mobile app.

Can Eagle-IoT be integrated with our existing supply chain management systems?

Absolutely. Eagle-IoT is designed to integrate seamlessly with existing systems. This allows for a unified approach to managing supply chain operations and easy data exchange across platforms.

What types of notifications and alerts can I configure in Eagle-IoT?

Eagle-IoT allows you to set up customizable notifications and alerts based on various events such as geofence breaches, deviations from planned routes, temperature fluctuations, and more. Alerts can be received via email, SMS, or push notifications on the mobile app, ensuring you are always informed. one lines, email support, and online knowledge base resources.

How does Eagle-IoT help with predictive maintenance in the supply chain?

Eagle-IoT tracks vehicle usage, engine hours, and asset health in real time. By analyzing this data, the system helps predict when maintenance is due or when equipment is likely to fail, preventing costly breakdowns and unscheduled downtime. Predictive maintenance helps keep the supply chain running smoothly with minimal disruption.

How can Eagle-IoT assist in optimizing inventory management?

Eagle-IoT provides real-time visibility into the location and condition of your inventory across warehouses, vehicles, and distribution centers. This data-driven insight helps you reduce stockouts, prevent overstocking, and optimize the flow of goods, leading to better inventory control and improved customer satisfaction.

Is Eagle-IoT scalable for growing supply chain businesses?

Yes, Eagle-IoT is highly scalable and can accommodate the needs of small businesses as well as large enterprises with complex supply chain operations. Whether managing a handful of assets or thousands, Eagle-IoT can grow with your business, providing a flexible solution that adapts to your evolving needs.

How does Eagle-IoT contribute to sustainability in the supply chain?

By optimizing routes, reducing idle time, and monitoring fuel consumption, Eagle-IoT helps reduce your carbon footprint. The platform’s data insights also allow for better planning and resource allocation, minimizing waste and inefficiency throughout your supply chain operations.

What are the mobile app features of Eagle-IoT for the supply chain industry?

The Eagle-IoT mobile app allows for real-time tracking, route navigation, and notifications while on the go. Supply chain managers can monitor vehicle locations, receive alerts, and manage assets from anywhere, providing flexibility and control over supply chain operations even when away from the desktop.

Ready to Elevate Your Supply Chain with Eagle-IoT?