What is the importance of Axle Load Monitoring System?

Why Every Public Transporter Needs Load Monitoring in Saudi Arabia

As we all know, a rule has been passed in the Kingdom of Saudi Arabia regarding the monitoring of load. According to this new rule, it is mandatory for every public transporter to have their trucks integrated with the load sensors. But do you know why this is mandatory for all?

For anyone who is managing a fleet of heavy assets, what comes to your mind when you are budgeting? Often we think of combustibles and vehicle expenses but what about the maintenance and technical failure expenditures? When it comes to the heavy-duty assets, the most exposed part is the axles of a freight truck bearing stress whole time leading to hefty maintenance outlay.

An overloaded truck is a serious threat to other road users and infrastructure. As heavier the weight of the truck is, higher will be its kinetic energy resulting in the drastic consequences in case of a crash. For safe operation and maximizing the payload whilst avoiding fines for overloading, the monitoring of axle load is inevitable.

Benefits of Axle Load Monitoring:

Reduced Maintenance Costs: Overloaded vehicles put excessive stress on axles, leading to quicker wear and tear and expensive repairs. Axle load monitoring helps prevent overloading, extending vehicle life and reducing maintenance costs.

Improved Safety: Overloaded trucks pose a serious safety risk, increasing their stopping distance and potential for accidents. Axle load monitoring ensures safe operation by staying within weight limits.

Optimized Payload: By knowing the exact weight on each axle, companies can optimize cargo distribution for maximum payload without exceeding limits.

Reduced Fines: Overweight fines can be significant. Axle load monitoring helps avoid these fines by ensuring compliance with regulations.

Prevented Underhand Cargo: With real-time load data, companies can monitor loading and unloading events, preventing unauthorized or unreported cargo.

Infrastructure Protection: Overloaded trucks damage roads and bridges. Axle load monitoring helps protect infrastructure by ensuring vehicles stay within weight limits

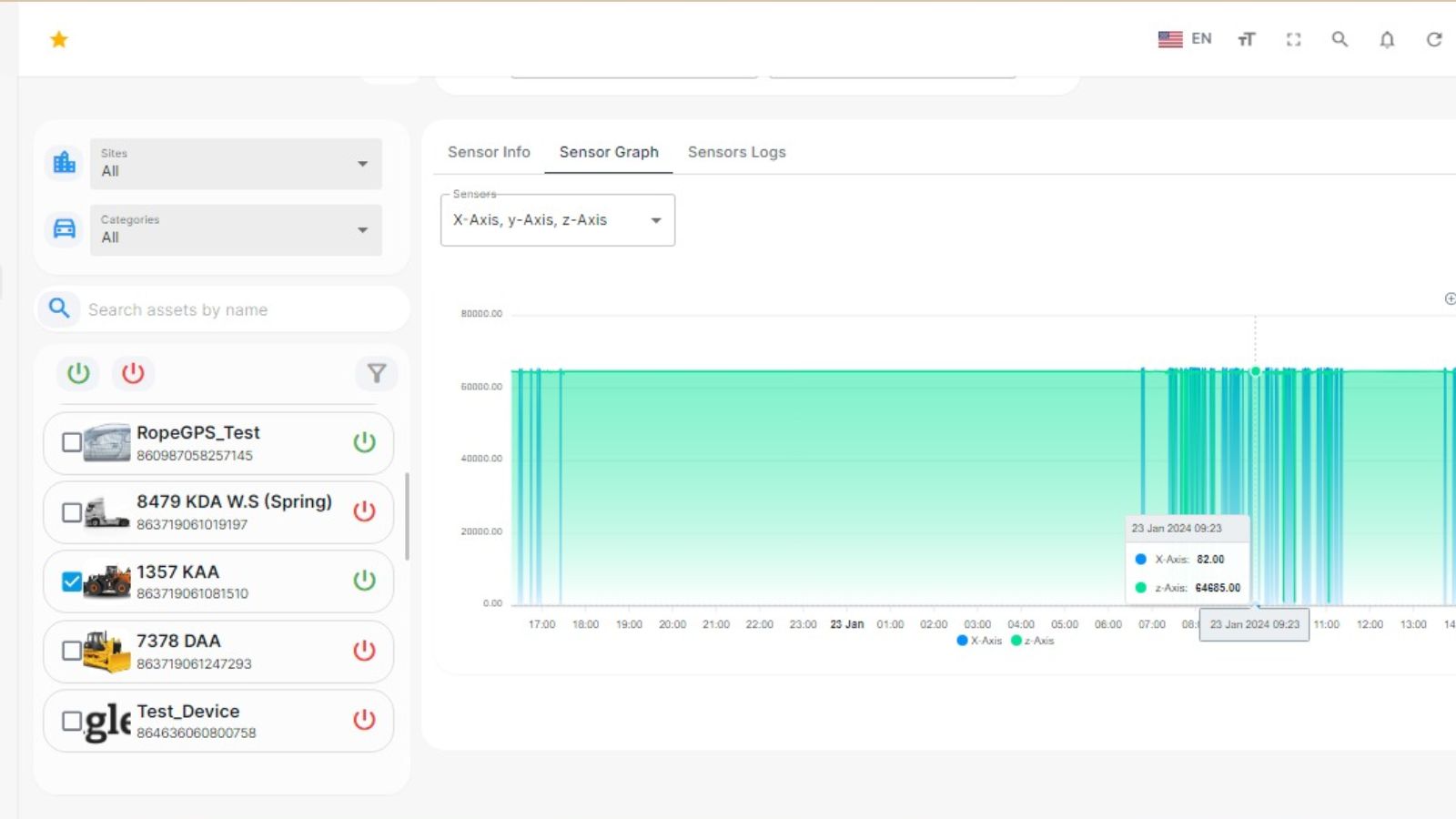

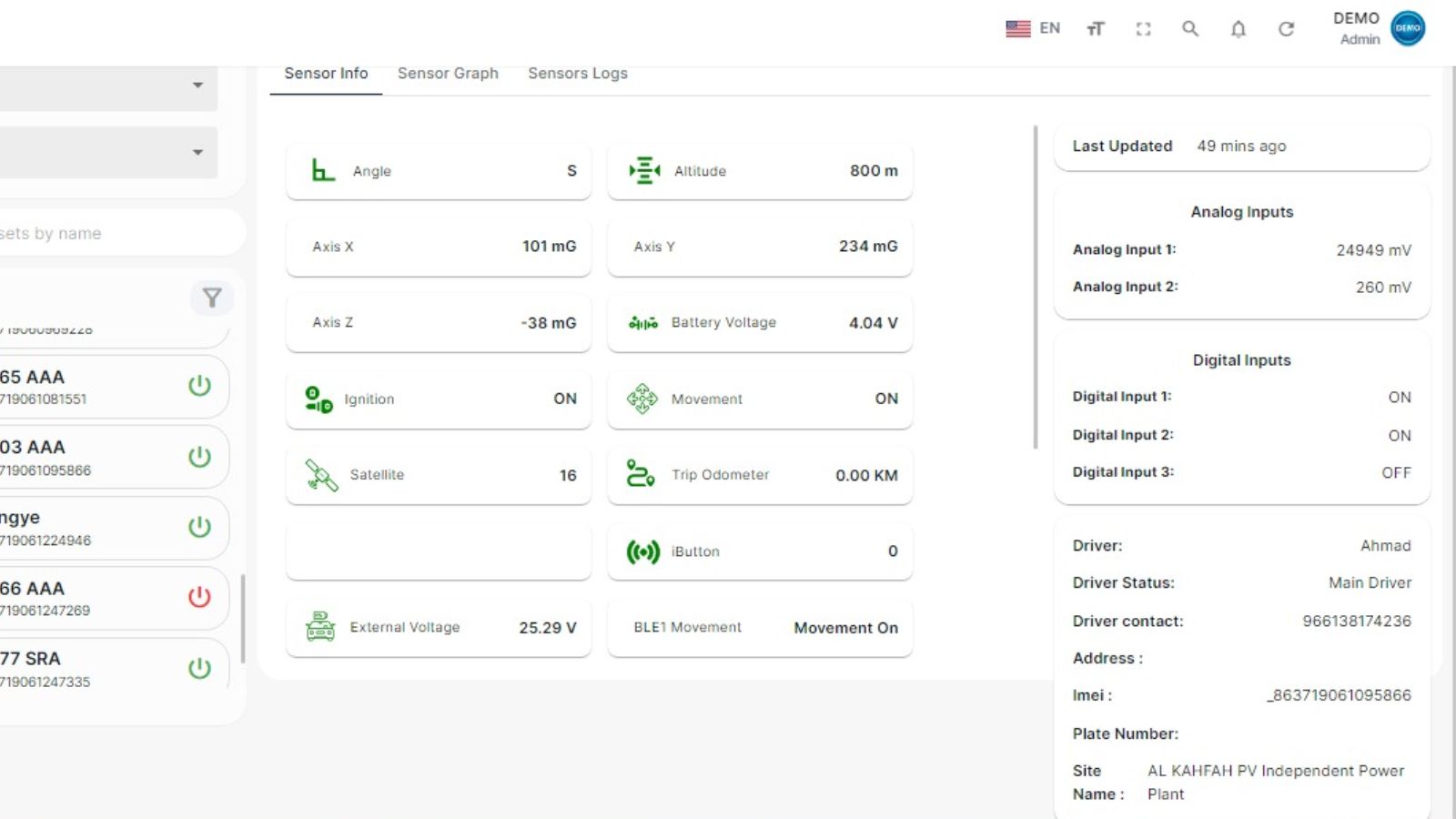

Eagle-IoT Axle Load Monitoring Solution

Eagle-IoT offers the monitoring of axle load with the integration of its advanced axle load sensors. With Eagle-IoT axle load monitoring, you can always monitor the excess load of the vehicle overall along with the load per axle. These load sensors are capable of sending data through a GPS tracker to the online monitoring system and/or to onboard driver’s display. Moreover, with its custom settings, you can receive an alert for loading and unloading events along with the event’s location of the map with respect to the time of the event. This information will help you in keeping the check of underhand cargo and will prevent the overloading of the vehicle. Thus depreciation of the vehicle and road infrastructure can be avoided and maintenance cost can be reduced.

Eagle-IoT axle load monitoring is not only limited to freight trucks but it is also appropriate for measuring the loads in dump trucks, garbage trucks, city buses, light-duty trucks, and municipal vehicles. Axle load monitoring is not only capable of preventing the breakdowns but will also optimize the cargo loads and prevents from hefty fines while exceeding the allowed axle load limits.

Would you like additional information about Eagle-IoT?

Call now at +966 56 638 7859

Or email us at news@dms-ksa.com

We are here to help.