The Evolution of Telematics: U.S. Market Insights and Opportunities for Saudi Arabia

Telematics technology has revolutionized fleet management worldwide, enhancing operational efficiency, safety, and compliance. A recent study on the U.S. market highlights key trends shaping the industry, particularly the shift towards video telematics as GPS-based tracking reaches maturity. These trends provide valuable insights for fleet operators worldwide, including those in Saudi Arabia, where the telematics market is still expanding.

U.S. Telematics Market: Key Trends and Developments

- Market Maturity and the Shift to Advanced Solutions

The U.S. telematics market has reached near saturation, particularly among large commercial fleets. Most fleet operators have already adopted GPS tracking, prompting a shift toward advanced solutions such as AI-powered video telematics, predictive analytics, and automation. These technologies offer deeper insights into fleet operations, helping companies improve safety, reduce costs, and streamline logistics.

- Video Telematics as the New Industry Standard

The adoption of video telematics has surged, particularly in the trucking industry. AI-driven dashcams and in-cab monitoring systems are being widely implemented to improve driver safety, reduce accident-related liabilities, and provide real-time data for insurance claims. With growing concerns over distracted driving and compliance enforcement, fleets are increasingly relying on video technology to enhance operational control.

- Competitive Market and Provider Switching

Despite the maturity of the market, U.S. fleets frequently switch telematics providers in search of better service, enhanced features, and competitive pricing. Customer expectations have risen, with demand for real-time data insights, customizable reporting, and seamless integrations with other fleet management tools. Providers that fail to innovate or address customer concerns face high churn rates.

- Challenges in Telematics Adoption

Resistance to telematics adoption still exists among certain fleets and driver groups, particularly due to concerns about privacy and surveillance. While companies recognize the operational benefits, some drivers view telematics as intrusive. However, education and incentive programs have played a crucial role in overcoming these objections, demonstrating how telematics protects drivers rather than simply monitoring them. +

-

- Financial Incentives and Cost Savings

Telematics systems have proven to deliver substantial financial benefits for U.S. fleets. These include reductions in insurance premiums, fuel consumption, and maintenance costs. Many insurers now offer lower rates to companies using video telematics and AI-powered monitoring tools, further driving adoption across industries.

Saudi Arabia’s Telematics Market: Opportunities for Growth

While the U.S. market is reaching saturation, Saudi Arabia’s telematics industry is still in a growth phase, presenting significant opportunities for businesses to implement advanced fleet management technologies.

- Increasing Telematics Adoption Across Industries

Saudi Arabia’s logistics, construction, oil & gas, and public transportation sectors are rapidly integrating telematics solutions to enhance efficiency and safety. Government regulations, including Vision 2030 initiatives to improve transportation and road safety, are driving increased adoption. Fleet operators are recognizing the long-term benefits of digital fleet management, leading to greater investment in telematics infrastructure.

- The Need for Video Telematics in Saudi Fleets

With road safety being a major concern, video telematics can play a crucial role in reducing accidents and enhancing driver accountability. AI-powered dashcams can help monitor driver fatigue, harsh braking, and distraction levels, allowing fleet managers to take proactive measures. The integration of video telematics can also support insurance claims and reduce liability costs, making it a valuable investment for businesses.

- Customization and Localization of Solutions

Unlike the U.S., where standardized solutions dominate the market, Saudi Arabia presents a unique opportunity for telematics providers to offer highly customized and localized solutions. Factors such as extreme weather conditions, long-haul desert routes, and cross-border logistics require telematics platforms that cater specifically to regional challenges. Service providers that can offer tailored features, such as heat-resistant hardware and multi-language interfaces, will gain a competitive edge.

-

- Addressing Resistance Through Awareness and Incentives

Similar to the U.S., telematics adoption in Saudi Arabia faces resistance from some drivers and fleet operators who view it as intrusive. However, clear communication about the benefits of telematics—such as protecting drivers from false accident claims and improving road safety—can help overcome these challenges. Offering incentives for safe driving behaviors, such as performance-based bonuses, can further encourage acceptance.

- Financial Benefits and Insurance Integration

The Saudi insurance sector is gradually recognizing the value of telematics-based risk assessments. By collaborating with insurers, fleet operators can secure reduced premiums based on real-time data analysis and accident prevention measures. As the market matures, insurers are expected to introduce more telematics-driven pricing models, making fleet telematics adoption financially beneficial for businesses.

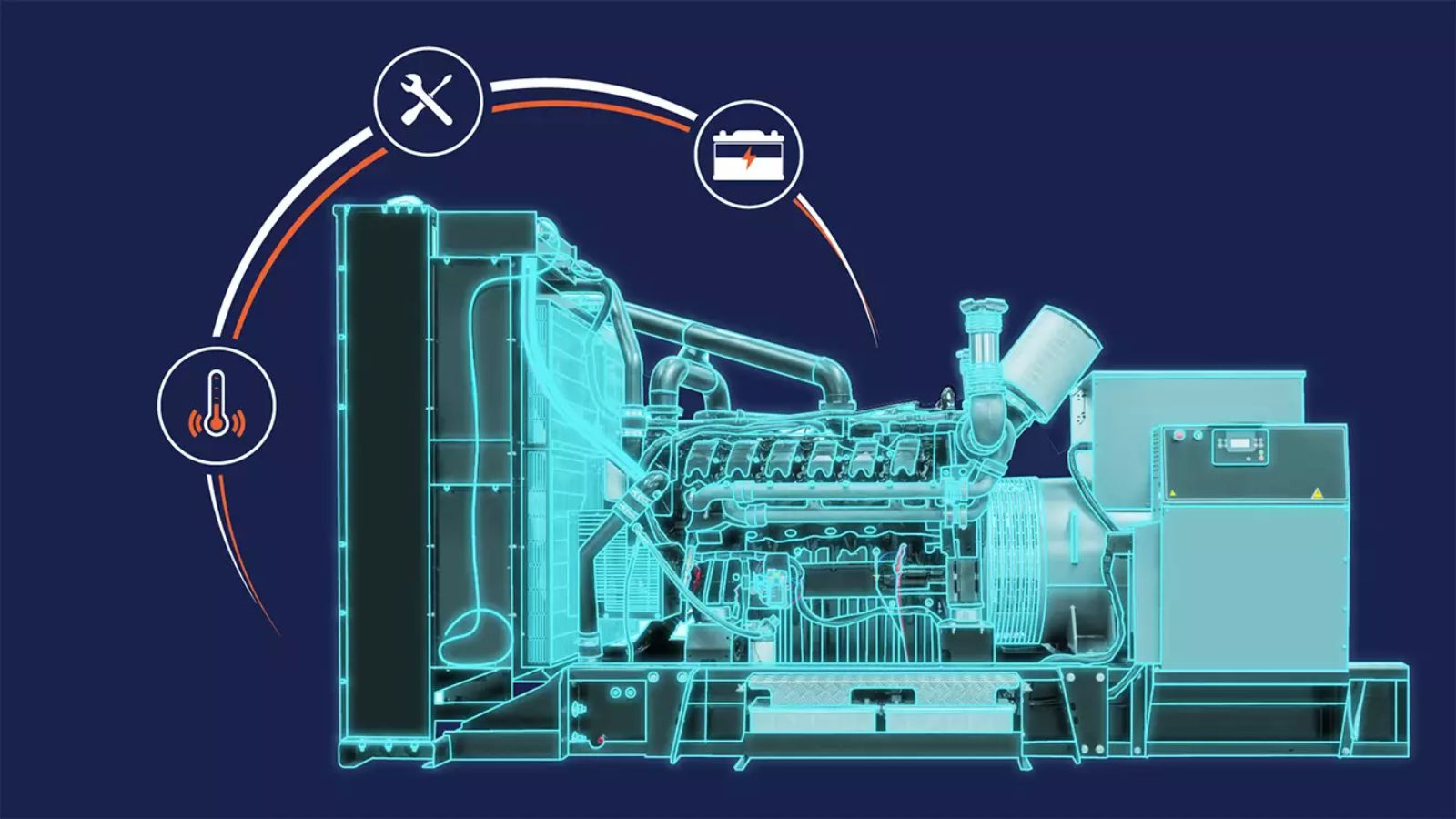

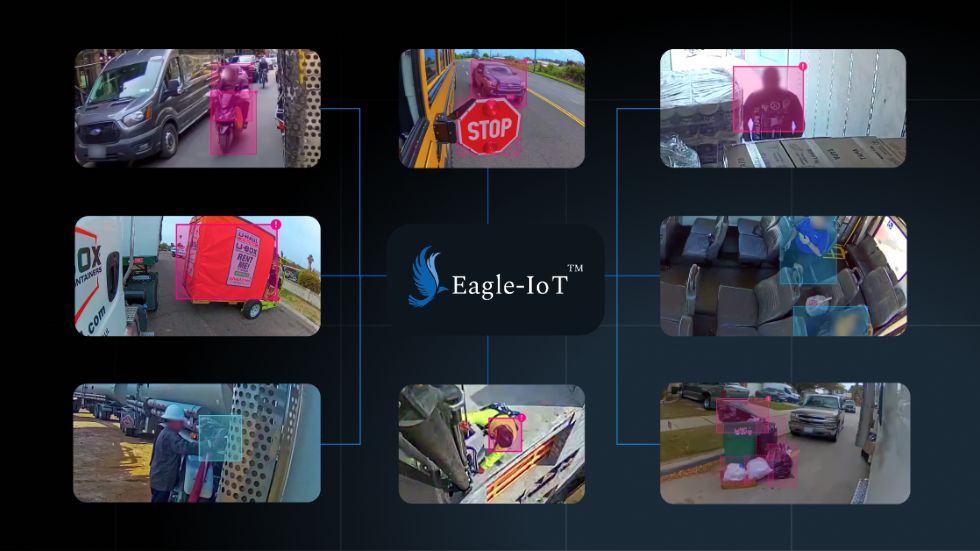

How Eagle-IoT is Leading the Telematics Transformation

Eagle-IoT is at the forefront of Saudi Arabia’s telematics evolution, offering state-of-the-art fleet management solutions tailored to local market needs. With an emphasis on AI-driven video monitoring, GPS tracking Eagle-IoT helps businesses:

- Enhance driver safety through real-time monitoring and AI-powered insights

- Optimize operational efficiency by providing data-driven analytics on fleet performance

- Reduce costs by integrating fuel management, route optimization, and automated reporting

- Ensure compliance with Saudi Arabia’s evolving transportation regulations

As telematics adoption continues to grow in the Kingdom, Eagle-IoT remains committed to delivering innovative, scalable, and localized solutions that drive efficiency, safety, and cost savings for fleet operators. The future of fleet management in Saudi Arabia is digital, and Eagle-IoT is leading the way in this transformation.

For more information on how Eagle-IoT can transform your fleet operations, contact us today to explore our cutting-edge telematics solutions tailored for your business needs.