Eradicating Downtime: Eagle-IoT’s Data-Driven Approach to Fleet Maintenance

Any fleet manager understands the frustration of downtime. A grounded vehicle translates to lost productivity, increased costs, and unhappy customers. However, measuring and tackling downtime can be a complex challenge. It’s not just about service history; it’s a tangled web of factors including delays getting vehicles to the shop, parts shortages, and even the effectiveness of daily inspections.

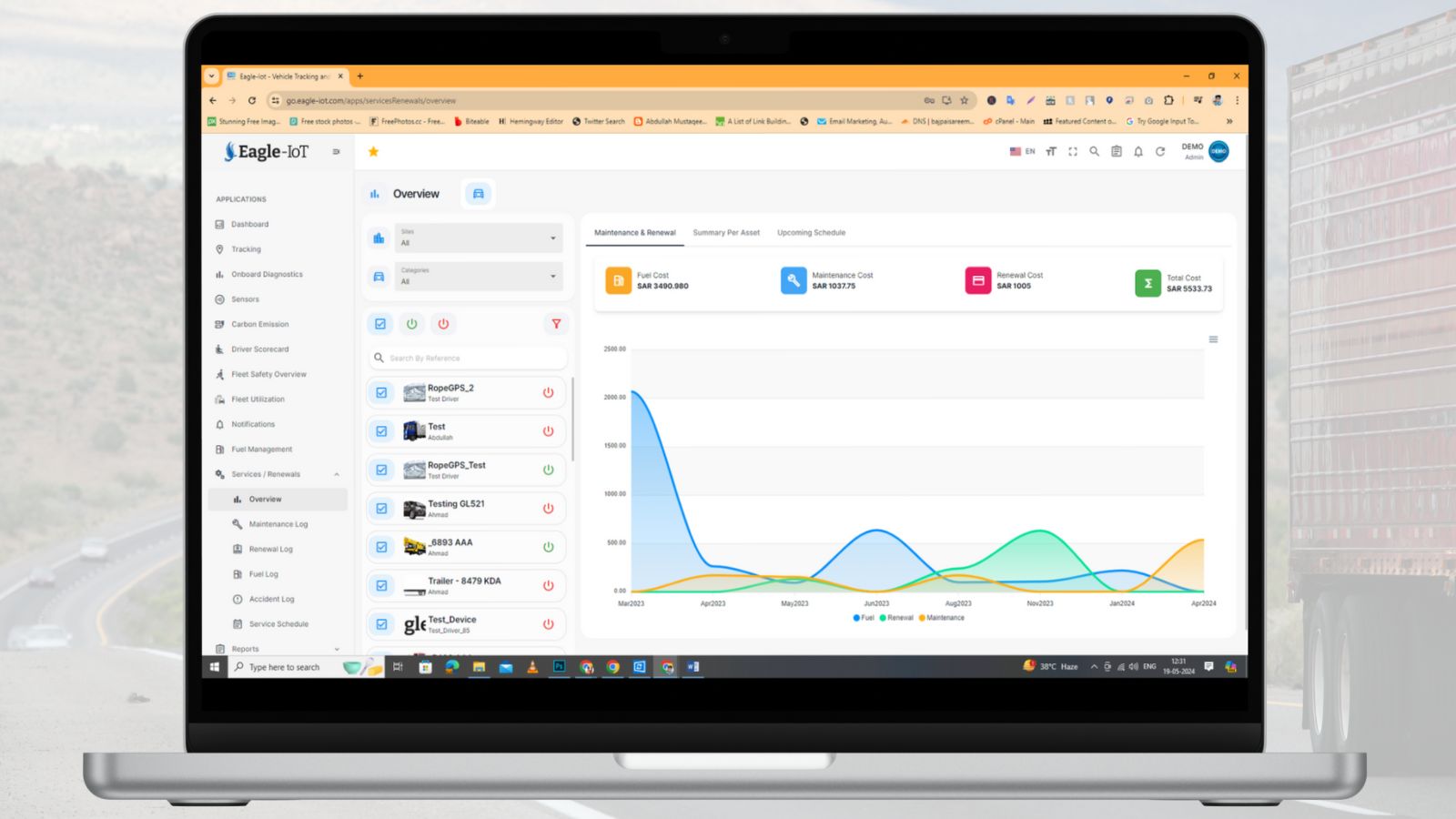

Traditionally, gathering and analyzing this data involved sifting through mountains of paperwork and spreadsheets. Thankfully, technology offers a smarter solution. Fleet management software (FMS) and telematics systems from providers like Eagle-IoT can automate data collection, consolidation, and presentation, giving you a clear, real-time picture of your fleet’s downtime metrics.

Here’s how Eagle-IoT empowers fleets to conquer downtime:

Benchmarking Downtime for Targeted Improvement

The first step is understanding your current downtime landscape. Eagle-IoT gathers data on everything from service histories and PM schedules to fault alerts and repair delays. This comprehensive view allows you to identify areas for improvement. By implementing Eagle-IoT, fleets can extend their vehicles lifecycle by 35%.

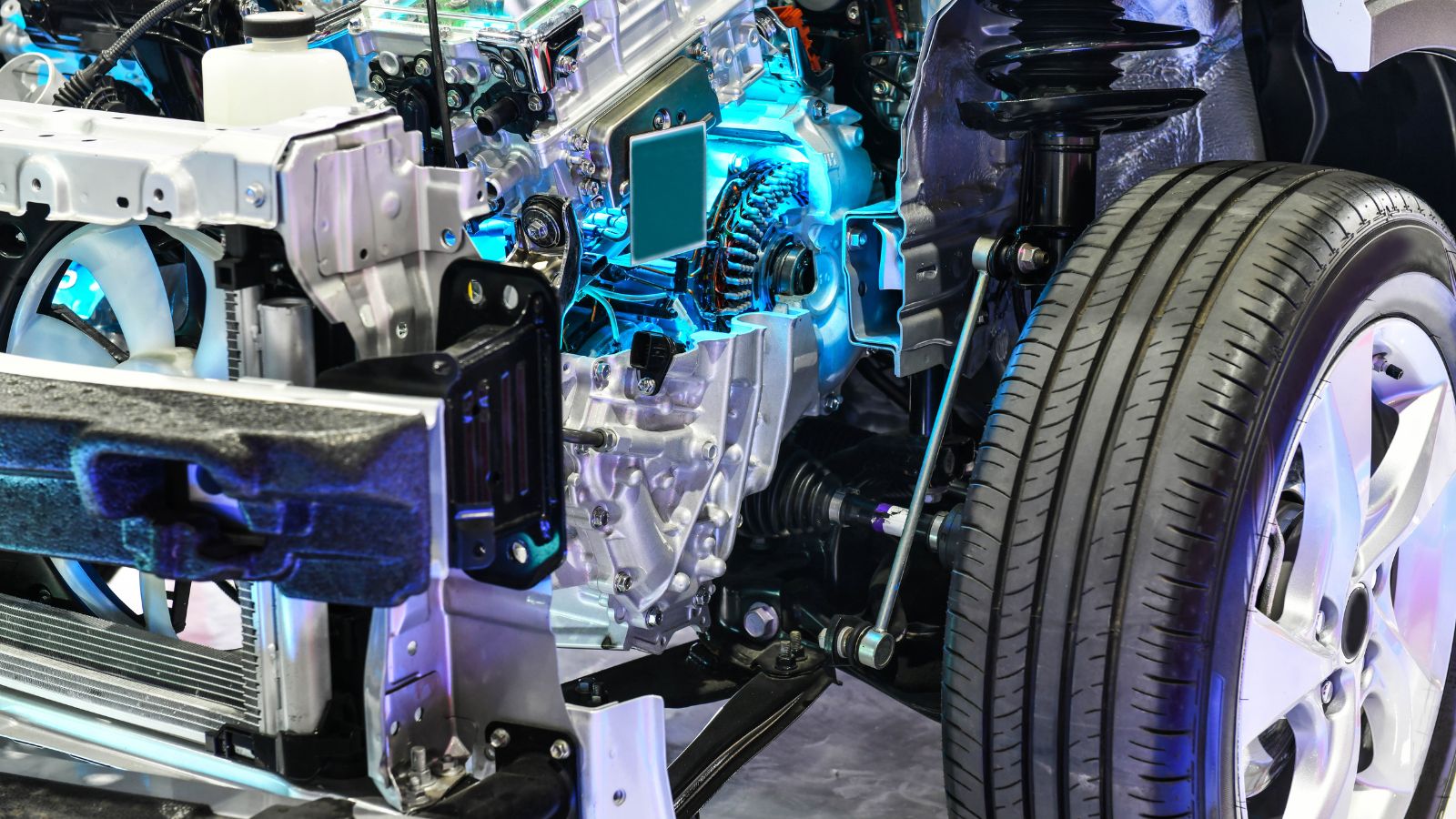

Pinpointing the Culprits: PM Practices and Inspections

Eagle-IoT dives deep to reveal the root causes of downtime. Often, the biggest culprit is inconsistent adherence to preventive maintenance (PM) schedules. Incomplete daily inspections can also lead to unexpected breakdowns.

Eagle-IoT helps fleet create customized inspection checklists for each vehicle type, ensuring a thorough examination that addresses the specific needs and potential weak points of each asset.

Eagle-IoT’s CMMS software also eliminate the “out-of-sight, out-of-mind” problem encountered with handwritten reminders. Automated PM alerts ensure timely maintenance for every vehicle in the fleet.

Shop Downtime: More Than Meets the Eye

Shop downtime, often overlooked, offers valuable insights. Eagle-IoT’s CMMS work order system tracks downtime caused by delays in parts acquisition or technician availability. This data empowers you to optimize parts sourcing and staffing levels, minimizing time spent waiting in the shop.

Here are some additional data points Eagle-IoT tracks to give you a complete downtime picture:

- Estimated vs. Actual Service Times: Identify bottlenecks in the repair process.

- Mechanic Assignment Delays: Understand technician workload and optimize scheduling.

- Towing Downtime: Track breakdowns and plan for contingencies.

- Extended Downtime: Analyze unexpected repair issues and adjust PM schedules accordingly.

Eagle-IoT automatically capture traditional work order details, along with estimated vs. actual service times, delay reasons, and unscheduled repairs. This rich data paints a clear picture of your service history and downtime trends.

Planning and Analysis: Turning Data into Action

Data-driven insights are key to proactive downtime management. By benchmarking your downtime metrics, you can not only reduce it but also be better prepared for the unexpected. For instance, Eagle-IoT helps identify optimal backup vehicle stock levels.

The ability to analyze trends and identify areas for improvement is what sets Eagle-IoT apart. Downtime planning and benchmarking are dynamic processes that adapt to your fleet’s evolving maintenance practices. The data you gather becomes the foundation for continuous improvement, allowing you to pinpoint and mitigate downtime triggers.

Extending Asset Lifecycles: The Downtime Advantage

Proper maintenance goes beyond minimizing downtime; it extends the lifespan of your assets, maximizing their ROI. Eagle-IoT helps you leverage downtime data to optimize PM schedules. Service history, inspection failures, and fault alerts all become valuable tools for identifying high-wear components and proactively addressing potential issues.

Eagle-IoT also allows you to create customized PM schedules for specific assets or groups. Automated alerts keep drivers and technicians informed of upcoming maintenance needs, ensuring tasks are completed on time. The impact? Reduced breakdowns and a longer lifespan for your vehicles.

The Takeaway: Downtime Doesn’t Stand a Chance

Effective downtime tracking, benchmarking, and reduction are the cornerstones of a successful fleet operation. Eagle-IoT empowers you to identify inefficiencies, leverage data for improvement, and extend asset lifecycles, ultimately maximizing fleet productivity.