How AI is Transforming Fleet Management for Small and Medium-Sized Businesses

Artificial Intelligence (AI) is revolutionizing the fleet management industry, offering automation, efficiency, and enhanced safety. While large enterprises often have dedicated fleet managers, small and medium-sized businesses (SMBs) typically lack the resources to hire personnel solely for fleet operations. AI-driven fleet management solutions bridge this gap, allowing SMB owners to oversee their vehicles efficiently without added complexity.

AI-Driven Fleet Management for Small Businesses

Many small and medium-sized businesses (SMBs) rely on commercial vehicles for daily operations, whether in plumbing, landscaping, HVAC, or moving services. Unlike large corporations with dedicated fleet managers, these businesses require solutions that minimize manual intervention while maximizing productivity. AI enables fleet management software to function as a virtual fleet manager, automating essential tasks such as tracking, compliance monitoring, and safety enforcement.

Fleet owners can gain real-time insights into vehicle usage, driver behavior, and customer interactions. This ensures smoother operations without the need for constant manual supervision.

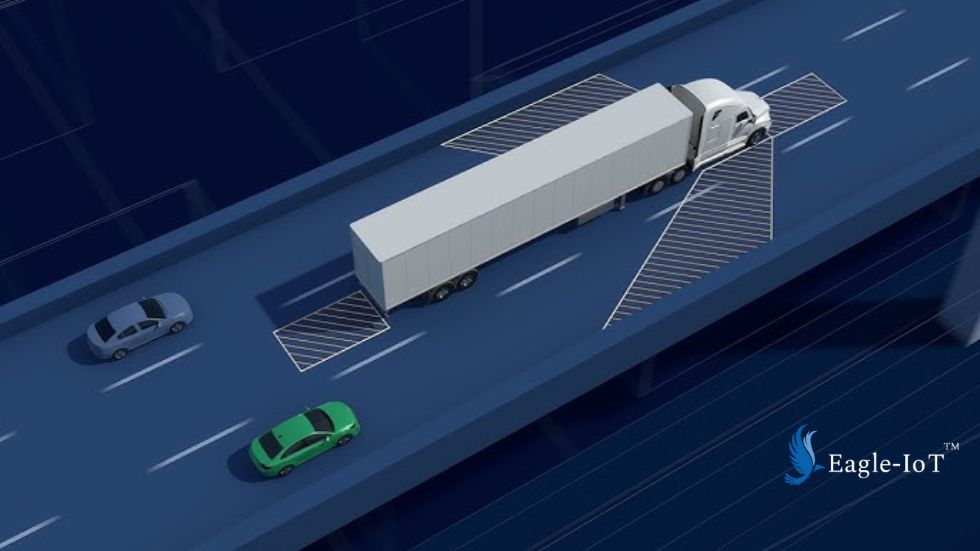

AI-Powered Driver Coaching & Safety Monitoring

Driver safety is a top priority for any fleet-based business. Traditionally, fleet managers manually review driver reports and intervene when necessary. However, for owner-operators managing multiple responsibilities, this process can be overwhelming. AI-powered dash cams and tracking systems provide real-time driver coaching, significantly reducing the workload for business owners.

Real-Time Driver Coaching

- AI-equipped dash cams monitor driver behavior in real time.

- Audio and visual alerts inside the vehicle notify drivers of risky actions such as speeding, harsh braking, or distracted driving.

- Automated coaching ensures that drivers self-correct their behavior without requiring immediate intervention from the fleet owner.

Customizable Alert Systems

- Business owners can set thresholds for alerts.

- First-time offenses may trigger only a warning, while repeated infractions notify management.

- AI-driven reports help owners identify high-risk drivers and implement corrective measures before accidents occur.

By incorporating AI into driver safety programs, businesses can significantly reduce accident rates, lower insurance costs, and improve overall road safety.

AI-Driven Customer Communication & Route Optimization

For service-based businesses, efficient route planning and timely communication with customers are crucial. AI enhances fleet management by automating these processes, ensuring that vehicles reach their destinations on time while keeping customers informed.

Automated Customer Notifications

- AI-powered systems provide customers with real-time ETA updates.

- Automated messages inform customers of delays, reducing frustration and improving service satisfaction.

- This minimizes the need for manual follow-ups and allows business owners to focus on core operations.

Route Optimization

- Analyze traffic patterns, road conditions, and delivery schedules to determine the most efficient routes.

- Reduces fuel consumption and operational costs by minimizing unnecessary mileage.

- Helps businesses manage more service calls per day, increasing revenue potential.

By leveraging these insights in route planning, SMBs can enhance their service quality, streamline operations, and improve customer retention.

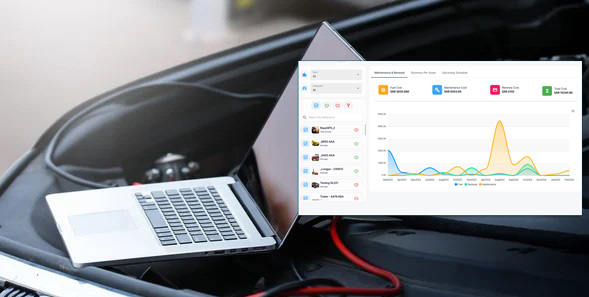

AI’s Role in Operational Efficiency

AI-driven automation is transforming how businesses handle fleet management. From scheduling maintenance to tracking vehicle performance, AI ensures that fleets operate at peak efficiency.

-

Automated Maintenance Scheduling

- AI monitors vehicle diagnostics and schedules preventive maintenance before breakdowns occur.

- Reduces unexpected repair costs and prolongs the lifespan of fleet vehicles.

- Prevents downtime, ensuring continuous business operations.

Fleet Utilization Insights

- AI-powered analytics track vehicle usage and identify underutilized assets.

- Helps business owners optimize fleet size, reducing unnecessary expenses.

- Ensures that each vehicle is used efficiently to maximize ROI.

Fleet management solutions allow SMBs to make data-driven decisions, ultimately increasing productivity and profitability.

The Future of AI in Fleet Management

AI-driven fleet solutions are creating new opportunities and specialized roles, such as data analysts and AI programmers. Generative AI is poised to redefine the industry, offering even more advanced automation and decision-making capabilities, including the potential for autonomous fleet management and advanced predictive analytics.

Small and medium business interests in fleet management can be significantly advanced through the strategic implementation of AI. A phased approach, carefully balancing innovation with practical considerations, will be key to maximizing the benefits.

- Phase 1: Boosting Efficiency and Proactive Maintenance (Next 12-24 Months)The initial focus for SMBs should be on leveraging AI to streamline operations and implement proactive vehicle care. This involves integrating AI-powered solutions to:

- Optimize Routing and Fuel Usage: AI algorithms can analyze real-time traffic, weather, and delivery schedules to create dynamic routes, minimizing fuel costs and delivery times – a crucial advantage for SMBs with limited resources.

- Predictive Vehicle Maintenance: AI can monitor vehicle data from onboard sensors to predict maintenance needs before they escalate into costly breakdowns, reducing downtime and repair expenses – a significant benefit for SMBs with smaller fleets.

- Automated Compliance and Reporting: AI-driven tools can automate compliance reporting and regulatory adherence, saving valuable administrative time and ensuring accuracy, particularly helpful for SMBs with limited staff.

- Enhanced Customer Communication: AI-powered chatbots and virtual assistants can improve customer interactions by providing real-time updates, answering questions, and resolving issues efficiently, enhancing customer satisfaction – a key differentiator for SMBs. Phase 2: Embracing Autonomy and Advanced Analytics (Long-Term Vision) The long-term vision for SMBs involves a transition toward more autonomous and data-driven fleet operations. This may include:

- Exploring Autonomous Fleet Management Systems: As these systems become more accessible, SMBs can investigate and potentially pilot AI-driven software that can make real-time decisions, optimize operations, and even dispatch vehicles autonomously.

- Considering Autonomous Vehicle Integration: While likely a longer-term prospect, SMBs should stay informed about developments in autonomous vehicle technology and assess how these vehicles could potentially transform their logistics and service delivery models.

- Leveraging Advanced Predictive Analytics: As generative AI becomes more readily available, SMBs can utilize these tools to develop predictive analytics capabilities that anticipate fleet needs and potential challenges, enabling proactive resource allocation and risk management.

Key Considerations for SMBs:

- Data Management: A practical data management strategy is essential for SMBs to effectively collect, process, and utilize fleet data. Cloud-based solutions can be particularly beneficial.

- Strategic Partnerships: SMBs can partner with AI technology providers to access advanced solutions and expertise without requiring extensive in-house development.

- Skills Development: SMBs should invest in training and development programs to ensure their staff can effectively manage and utilize AI-driven fleet technologies.

Challenges of AI Implementation

- While the benefits of AI in fleet management are substantial, SMBs should also be aware of potential challenges:

- Data Privacy: Collecting and analyzing driver and vehicle data raises privacy concerns that must be addressed through transparent policies and secure data management practices.

- Cost of Implementation: The initial investment in AI-powered fleet management solutions can be significant, requiring careful evaluation of ROI and budgeting.

- Employee Training: Employees need proper training to effectively use and interpret the data provided by AI systems. Change management is crucial for successful adoption.

- Integration with Existing Systems: Integrating AI solutions with existing fleet management systems or other business software can sometimes be complex.

By strategically implementing AI in their fleet management, SMBs can achieve significant improvements in efficiency, cost savings, safety, and customer satisfaction, positioning themselves for sustainable growth and competitiveness in the evolving marketplace.

Final Thoughts on AI in Fleet Management

AI is actively transforming fleet management. For SMBs, AI-driven solutions provide the automation and efficiency needed to manage vehicles effectively. By leveraging AI for driver safety, route optimization, customer communication, and operational efficiency, businesses can reduce costs, improve service quality, and enhance productivity. Addressing the challenges proactively will be key to realizing the full potential of AI in fleet management. Businesses that adopt AI-driven solutions today will be at the forefront of this transformation.