The Power of Live Tracking: A Closer Look at Real-Time Visibility with Eagle-IoT

-

The Rising Need for Real-Time Visibility

In the world of fleet operations, the margin for error is shrinking. Today’s businesses—whether in logistics, construction, healthcare, or public services—must operate with agility and clarity. The ability to monitor moving assets in real time is no longer a premium advantage but a core operational need. Every delay, miscommunication, or deviation can impact productivity, escalate costs, or worse, compromise safety.

-

A Day in the Life of Fleet Operations

In a case study we observed the daily routine of a regional transportation manager, named Firas, overseeing a mixed fleet of cargo trucks and service vans. His teams operate across different cities, responding to delivery schedules and customer needs on tight timelines. One morning, a client calls to report a delayed shipment. Without real-time visibility, Firas is left with only his drivers’ updates and vague time estimates. As customer frustration grows, he realizes how much hinges on not just knowing where the vehicles are—but having immediate, centralized access to that information.

-

In another instance, a customer reported that he runs a fleet of waste collection vehicles. A resident calls to complain that a collection was skipped. The operations supervisor, unable to confirm the vehicle’s exact path that day, is left relying on driver reports and route plans. Without a digital trail, accountability becomes challenging. These situations are not uncommon, and they highlight a shared need: a live, reliable, and accessible tracking system that works in real time and on demand.

What Live Tracking Should Look Like

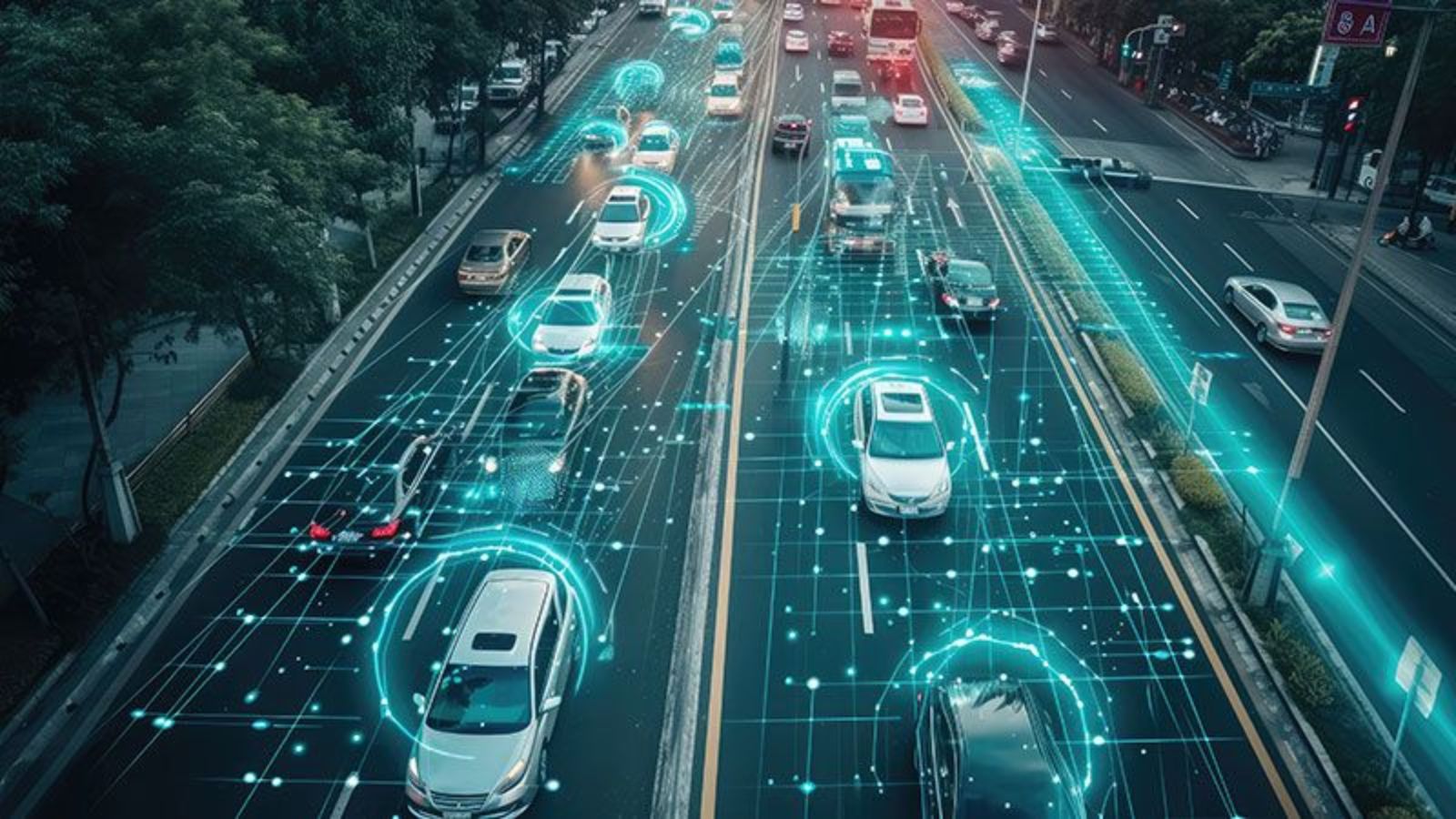

Eagle-IoT addresses these challenges with an integrated, non-intrusive platform that emphasizes clarity and usability. One of its key features is a stable, responsive live tracking map where users can follow vehicles as they move—without losing zoom level, map position, or screen continuity. Fleet managers can zoom into specific areas, follow the exact route of a single vehicle, and monitor performance across regions without technical disruptions or refresh-induced map resets.

The functionality extends beyond just visual tracking. The system provides trail history, enabling users to view the exact path a vehicle has taken, complete with timestamps. This is particularly useful during investigations, delivery disputes, or operational reviews. If a vehicle has strayed from its assigned route or made an unscheduled stop, this information is readily accessible, allowing decision-makers to identify causes and take corrective action.

-

A Centralized View with the Eagle-IoT Control Room

Complementing the live tracking experience is the Control Room feature—a centralized dashboard within Eagle-IoT that offers a complete, at-a-glance overview of the entire fleet. From this control panel, users can view a full list of active and inactive vehicles, track their current status, and visualize them directly on the map in real time. This holistic view transforms the way fleet operators manage their day-to-day operations. Instead of switching between screens or dealing with fragmented reports, they have everything they need in one intelligent interface.

Whether it’s dispatchers coordinating routes, supervisors reviewing driver behavior, or managers ensuring compliance, the control room feature enables a unified perspective. It also supports quick filtering and grouping, so teams can prioritize critical assets or zoom into regional fleets without losing operational visibility. It’s not just about knowing where the vehicles are—it’s about being in control of the movement, status, and performance of every single asset, all from one place.

Live tracking is evolving. It is no longer limited to blinking dots on a map—it’s about clarity, history, and control. Fleet Management Solutions like Eagle-IoT allow organizations to manage assets with greater foresight, reduce operational blind spots, and respond to real-world challenges in real time. When your fleet is always visible and your decisions are data-driven, operational excellence becomes not just possible—but sustainable.

-

To learn more about how Eagle-IoT is helping businesses build safer, smarter, and more connected fleet operations through intelligent monitoring and driver engagement tools, contact us today for a personalized consultation.