Elevate Cold Chain Operations with Wireless Temperature Sensors

Elevate Cold Chain Operations with Wireless Temperature Sensors

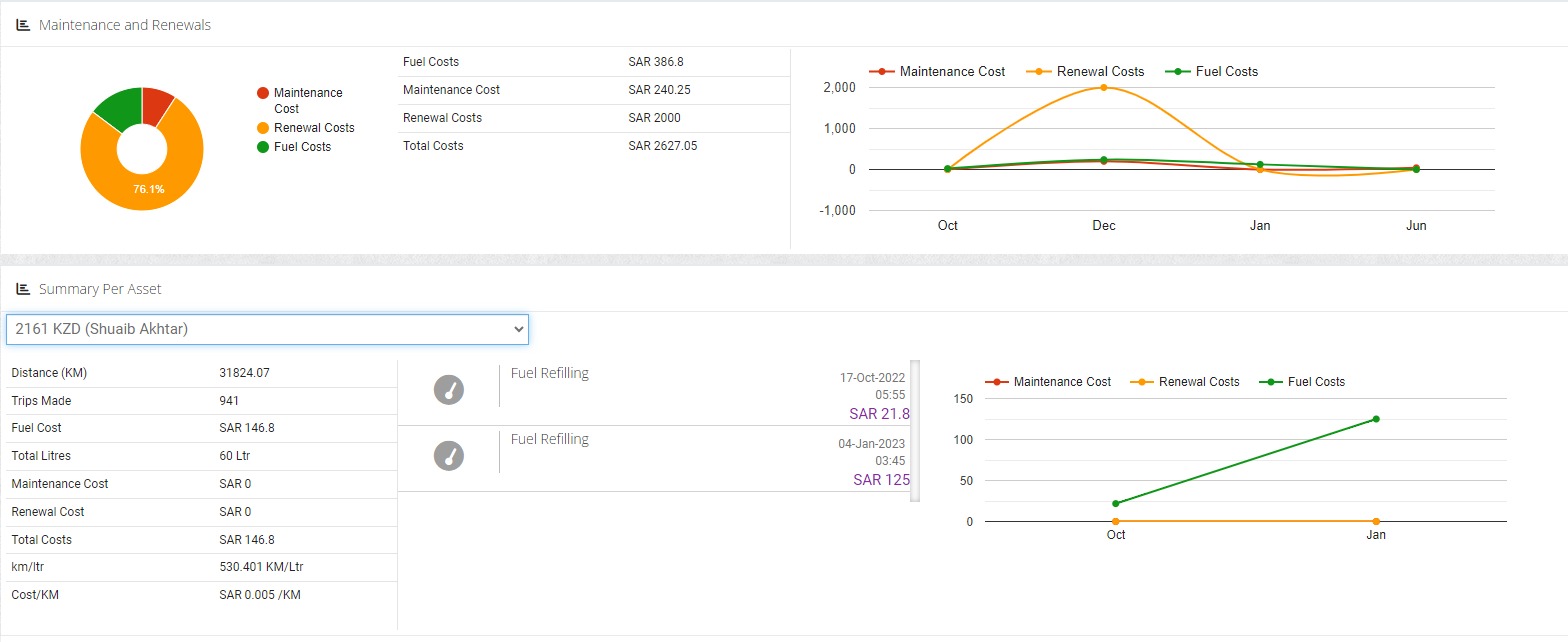

In the ever-evolving landscape of logistics and supply chain management, maintaining the integrity of the cold chain has become a critical factor in ensuring the quality and safety of temperature-sensitive products. Efficient cold chain management demands real-time insights and proactive measures. Traditional methods of temperature monitoring often fall short in delivering the necessary precision and immediacy required for the fast-paced nature of today’s supply chains. To address the complexities of this process, Eagle-IoT introduces an unparalleled solution for elevating cold chain operations.

Our cutting-edge technology incorporates the variety of sensors such as temperature, humidity, magnetic door, beacons and LoRa-based wireless temperature and humidity sensors to not only transform temperature-sensitive product management but also introduces a host of intelligent features to ensure a seamless and proactive approach to cold chain monitoring.

Eagle-IoT Cold Chain Monitoring Solution allows warehouse managers to seamlessly and automatically record temperature data across the entire cold chain. No longer do logistics teams need to rely on cumbersome manual record-keeping; instead, a unified, automated temperature logbook is generated, ensuring accurate and up-to-date information is always at your fingertips.

Building a Unified Ecosystem Across Your Cold Chain

Eagle-IoT doesn’t stop at providing individual solutions; it offers a fully integrated, unified temperature monitoring solution for the entire cold chain. As goods move from the warehouse to last-mile delivery vehicles, a cohesive ecosystem ensures consistent and reliable temperature control.

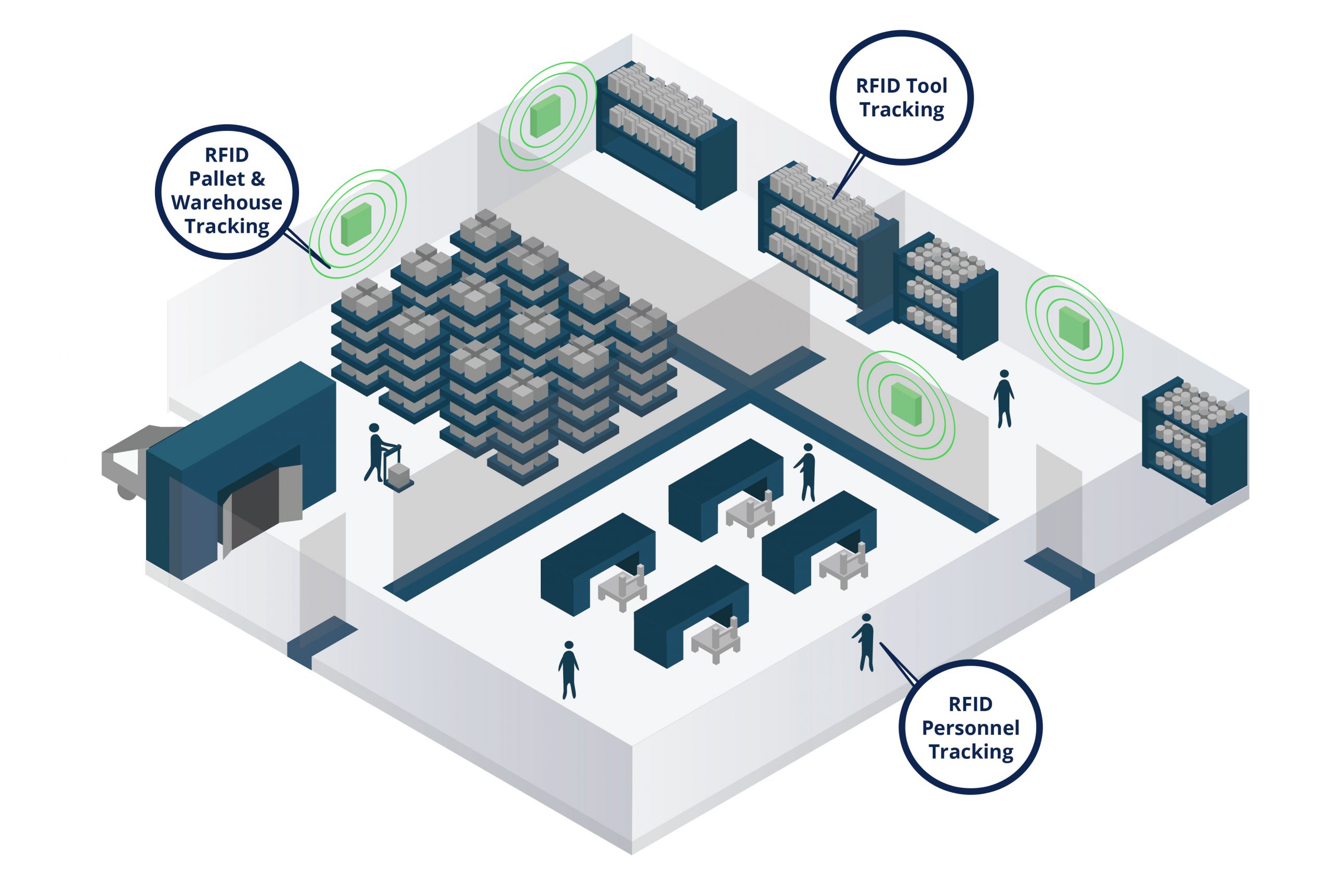

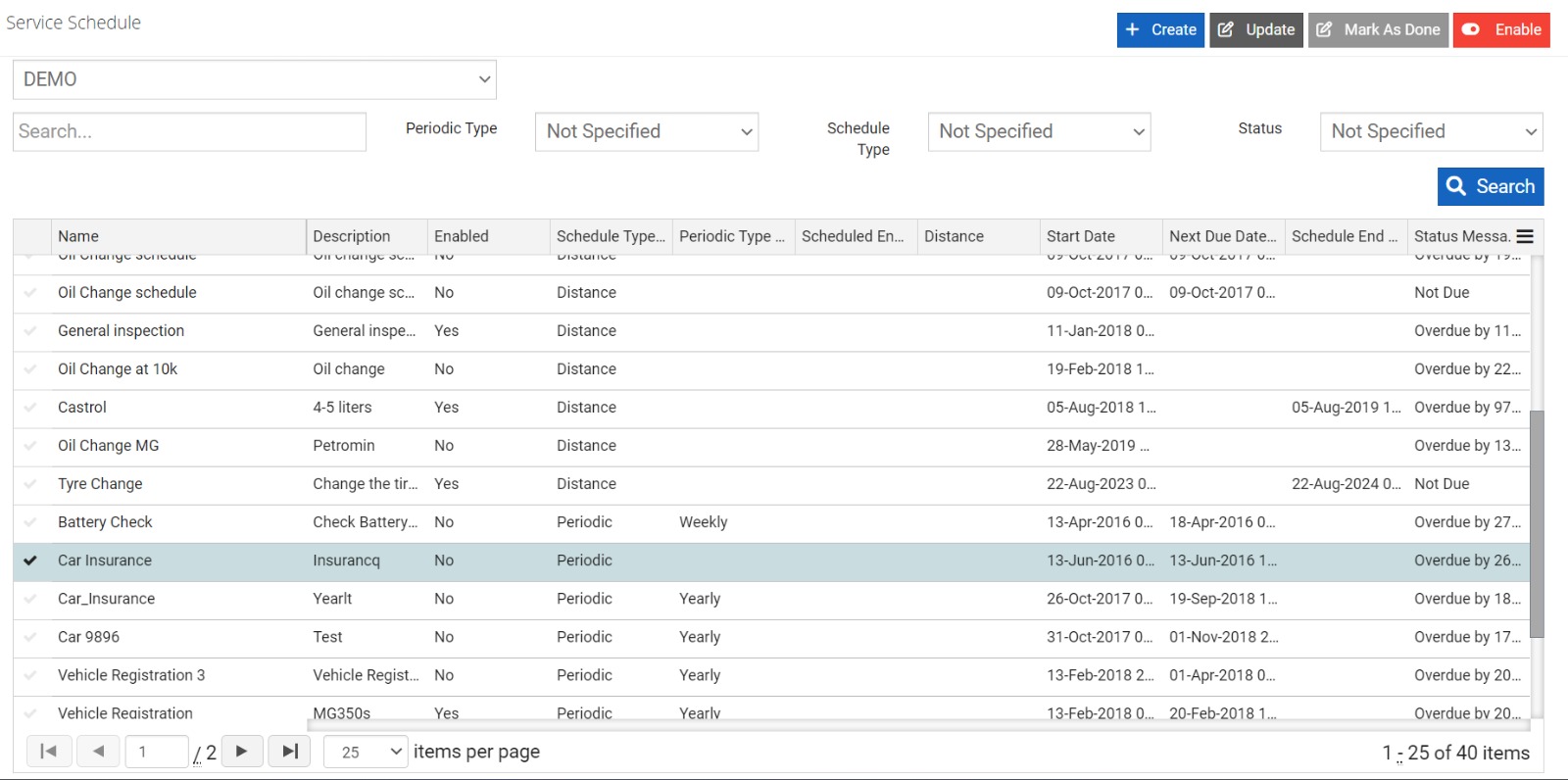

Smart Real-Time Monitoring of Doors and Movement of Forklifts

Eagle-IoT goes beyond traditional monitoring. Our one-stop solution ensures real-time awareness of crucial events such as door movements and the on-the-go activities of forklifts. This smart monitoring approach adds an extra layer of control, allowing you to track every movement within your cold storage facilities.

Proper Rack Management and Inventory Placement

Efficient cold chain management extends to proper rack utilization and inventory placement. Eagle-IoT’s intuitive system facilitates proper rack management, ensuring optimal use of space and strategic inventory placement for streamlined operations.

Monitoring of Water Leakage and Accumulation

Water leakage can pose a significant threat to the integrity of your cold chain. With Eagle-IoT, you can actively monitor and receive alerts for any water leakage or accumulation, ensuring the safety of your assets and preventing potential damage.

Running Status of Refrigeration Units and Access Control

Knowing the running status of refrigeration units is vital for maintaining optimal conditions. Eagle-IoT provides real-time insights into the performance of your refrigeration units. Additionally, our solution incorporates access control features, adding an extra layer of security to your cold storage facilities.

SFDA Compliance and Thermal Mapping

For businesses operating within Saudi Arabia, Eagle-IoT ensures compliance with SFDA (Saudi Food and Drug Authority) regulations. With the proactive approach users can set alerts for specific conditions such as freezer door openings or temperature spikes. not only prevents product loss but also aids in meeting regulatory compliance standards, simplifying the adherence to regulations.

Additionally, thermal mapping capabilities provide a visual representation of temperature distribution within your cold storage, ensuring compliance and product quality.

The Cold Chain Monitoring Solution offered by Eagle-IoT is scalable which makes it an ideal solution for businesses of all sizes, providing flexibility as your cold room monitoring needs evolve.

Create a wireless infrastructure that seamlessly integrates into existing operations, offering a sophisticated yet budget-friendly temperature monitoring solution today!