Ensure structural integrity by leveraging IoT in Ready-Mix Concrete

The Art of Precision: Achieving Perfect Concrete Mixes

When it comes to meeting the technical specifications for a given construction project, ready mix concrete is the art of choosing the types of ingredients, the right proportions to use them along with the right environmental conditions. To improve the strength, durability, and workability of ready-mix concrete one needs to ensure the quality of concrete during mixing, transporting, placing, and curing stays maintained.

The “70-in-7” Rule: A Flawed Approximation

It takes around 28 days for a normal slab of concrete to cure to full strength. But adhering to the “70-in-7” rule in ready-mix concrete, a slab will attain 70% of its maximal strength 7 days after it is poured which is just a rough approximation without considering particular environmental elements such as temperature, humidity and evaporation rate which affects the curating speed.

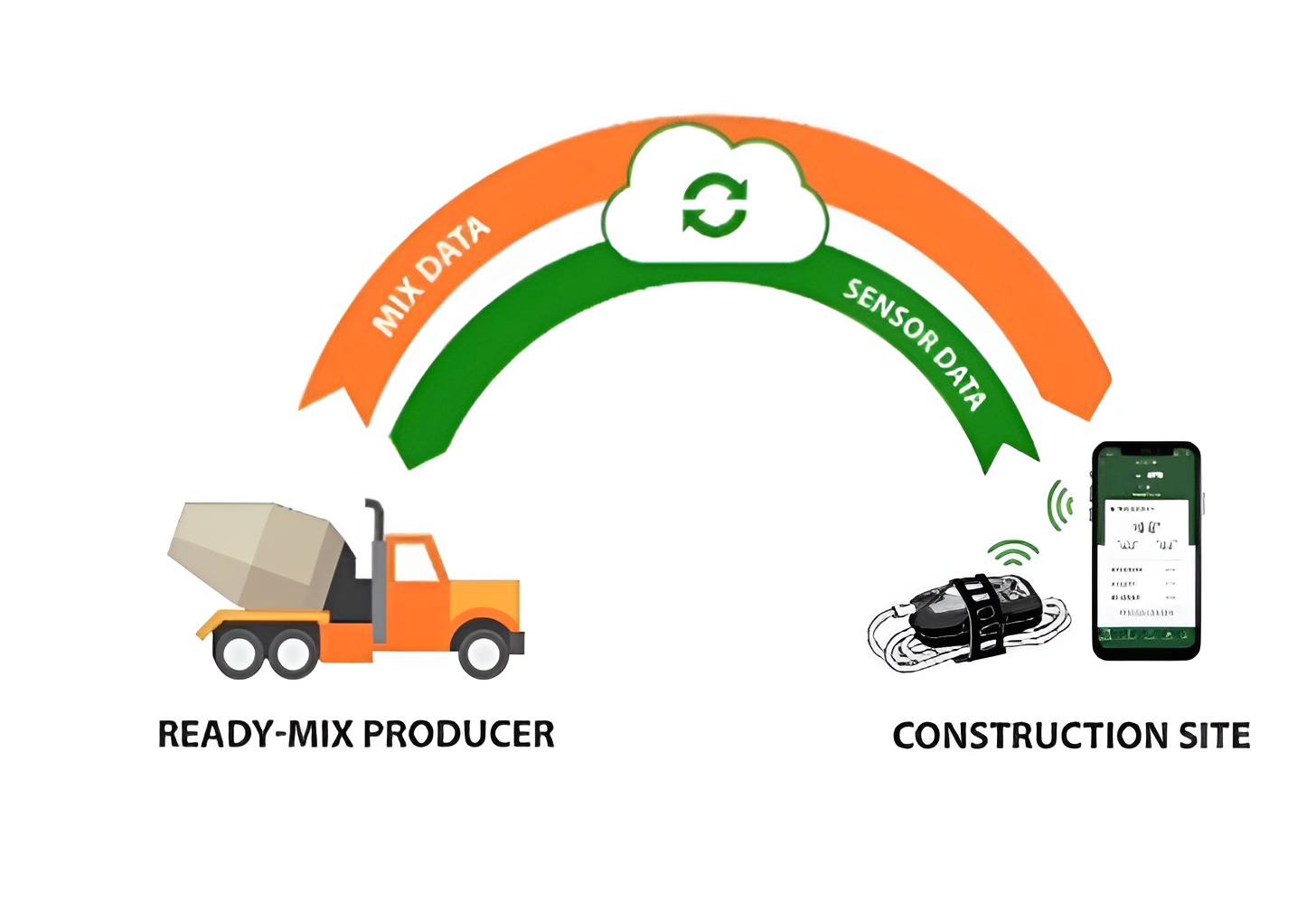

By leveraging IoT, the conventional construction industry can be revolutionized. IoT-based distributing sensors can be embedded within a slab at various lengths and depths before concrete is poured to gain visibility into concrete’s performance throughout the curing process.

Data-Driven Insights for Improved Efficiency and Cost Savings

The historical data of supply chain monitoring, job scheduling and order management can be sliced and diced to make effective KPIs to improve the bottom line. Besides this, the fleet data from ready-mix producers can be drilled down to specific drivers to improve their driver behavior or can represent a holistic view of your entire fleet. The data can be accessed via cloud from any device at any time.

Revolutionizing Construction with IoT Sensors.

Eagle-IoT ready-mix concrete management solution offers an efficient approach to the ready-mix fleet’s real-time collection of data. It allows you to manage slumps in transit and monitors load data over time with axle load monitoring solution. Alerts are generated when the threshold limit is breached.

Optimizing Curing Conditions for Peak Performance

To optimize the performance of ready-mix concrete to meet specific performance requirements, Eagle-IoT ready-mix monitoring solution allows you to keep a check on the drum rotation while the vehicle is stationary or in transit. A water flow meter can be used to monitor the water supplied to the concrete. Besides this temperature updates and alerts can also be generated automatically when a predetermined threshold temperature is breached. This real-time data helps contractors optimize critical operations.