When Generators Whisper Secrets: How Data Analysis Optimizes Production

The Critical Role of Reliable Generators in Industrial Success

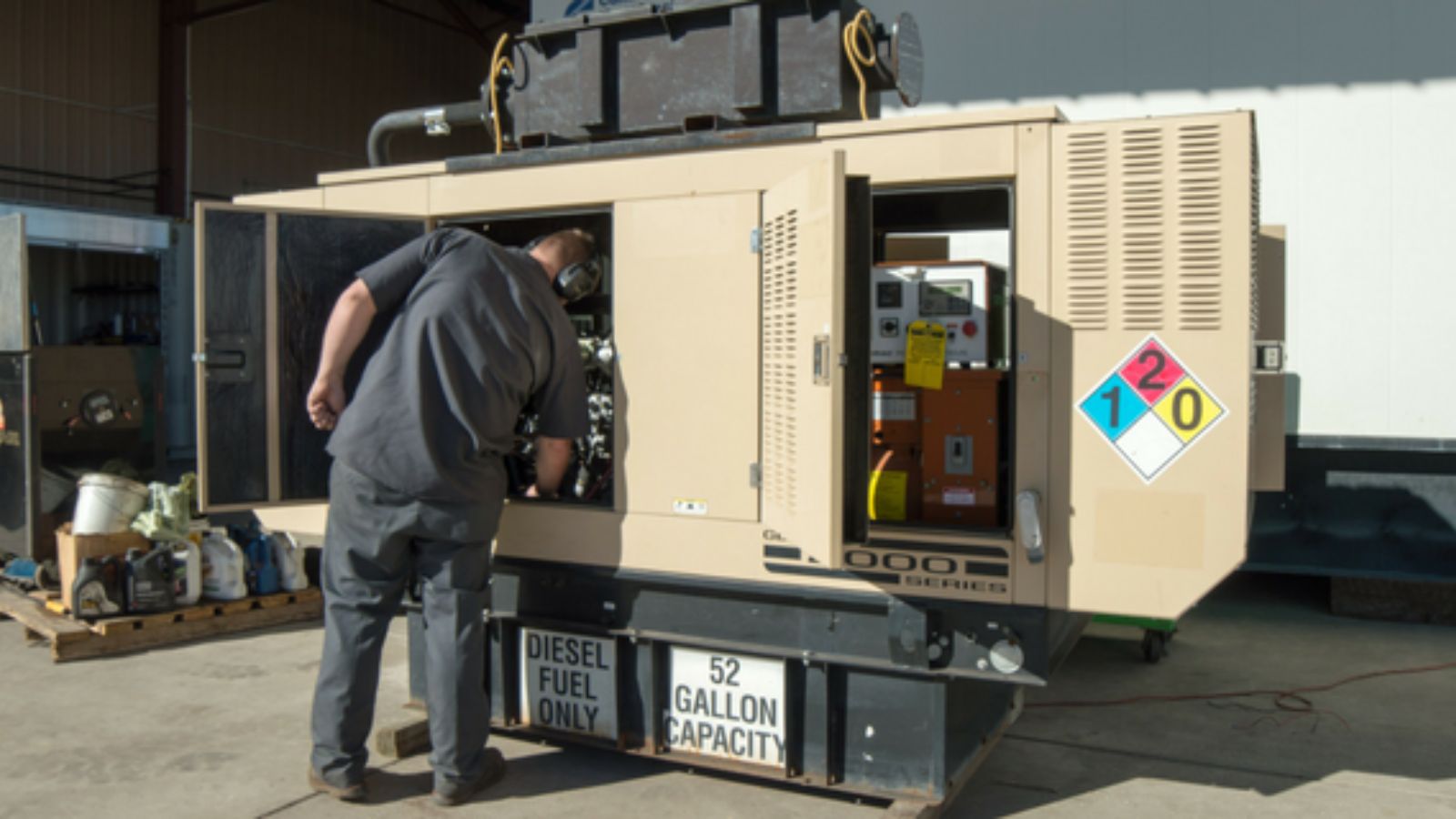

Industrial success hinges on the reliable operation of generators. From the colossal presses shaping steel to the delicate equipment crafting life-saving pharmaceuticals, these generators power a vast array of critical production processes. However, even the most robust generators require meticulous monitoring to ensure optimal performance.

The Devastating Impact of Downtime

An unexpected generator malfunction can halt the production line, leaving workers standing idle and causing operational bottlenecks that jeopardize deadlines, leading to a cascade of negative consequences translating to a multitude of detrimental effects:

- Financial Losses: Lost production time directly eats into profits.

- Operational Delays: Missed deadlines can damage relationships with suppliers and customers.

- Reduced Efficiency: Downtime disrupts workflows, hindering overall operational efficiency.

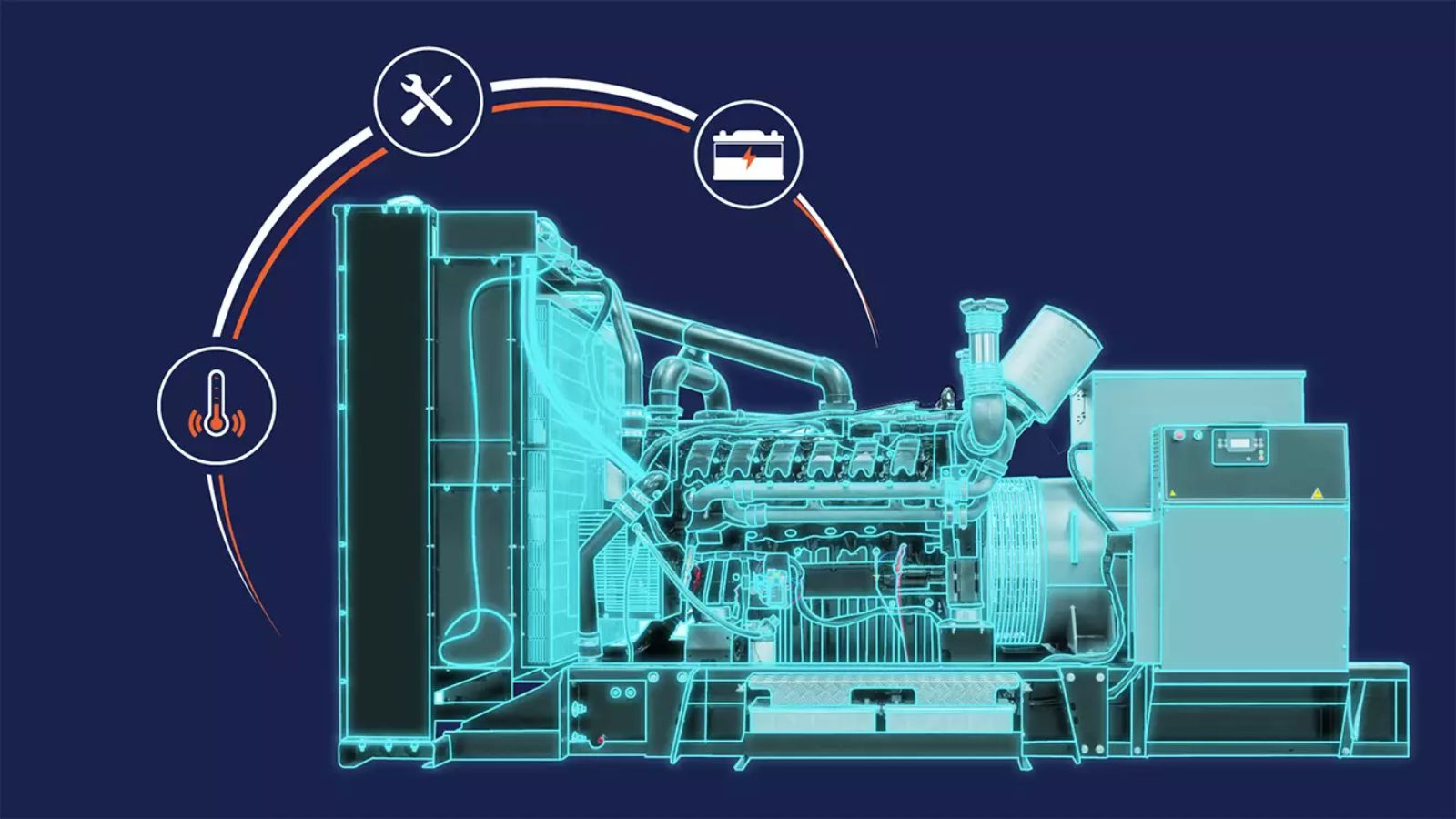

Eagle-IoT: Empowering Proactive Generator Management

This article explores how data-driven solutions, specifically the capabilities offered by Eagle-IoT’s Diesel Generator Monitoring solution, can empower industrial facilities to proactively manage generator health and maximize production efficiency.

Predicting the Future: From Reactive to Proactive Maintenance

Traditional reactive maintenance involves waiting for a generator to malfunction before initiating repairs. This approach can be disastrous, leading to costly downtime and potential damage to equipment. Predictive maintenance, on the other hand, leverages data and analytics to anticipate potential problems before they occur.

Eagle-IoT’s predictive capabilities offer several advantages to industrial facilities:

- Reduced Downtime: By anticipating potential issues, facilities can schedule maintenance during planned downtime windows, minimizing disruption to production schedules. .

- Optimized Maintenance Strategies: Predictive maintenance allows for targeted repairs, focusing on the specific components that require attention. This reduces unnecessary maintenance procedures and associated costs. .

- Improved Resource Allocation: Knowing when and where maintenance is needed allows for better allocation of maintenance personnel and resources.

The Power of a Connected Future with Eagle-IoT

The cloud-based platform of Eagle-IoT fosters a connected future for generator management. Data is securely collected and transmitted to the cloud, allowing for:

- Remote Monitoring: Access generator performance data and receive alerts from any location with an internet connection. This empowers facility managers to maintain oversight even when they’re not physically present on-site.

- Scalability and Flexibility: The cloud-based platform can seamlessly adapt to accommodate the growing needs of your facility. As your operations expand, Eagle-IoT can scale to monitor additional generators or integrate with other industrial equipment.

Investing in the Future of Reliability

Implementing a data-driven, predictive maintenance approach with Eagle-IoT is an investment in the future of your industrial operations. By prioritizing generator health and minimizing downtime, Eagle-IoT empowers facilities to achieve:

- Enhanced Production Efficiency: Reduced downtime translates to increased production output and improved overall efficiency.

- Lower Operational Costs: Predictive maintenance reduces the need for emergency repairs and associated costs. Optimized fuel consumption through Eagle-IoT’s insights further contributes to cost savings.

- Improved Sustainability: By extending generator lifespan and optimizing fuel usage, Eagle-IoT can contribute to a more sustainable industrial operation.

- Enhanced Product Quality: Unforeseen generator failures can disrupt critical processes, leading to inconsistencies and potential quality issues in the final product. By ensuring generator reliability, Eagle-IoT safeguards product quality and protects your brand reputation.

- Improved Workplace Safety: Generator malfunctions can pose safety hazards for workers. Proactive maintenance with Eagle-IoT minimizes these risks by addressing potential problems before they escalate into safety concerns.

- Customer Satisfaction: Reliable generators contribute to on-time production and delivery schedules, ultimately leading to happier customers. By minimizing disruptions, Eagle-IoT helps ensure you meet your customer commitments.

- Reduced Environmental Impact: Unplanned generator outages can sometimes lead to the use of backup power sources, which may be less environmentally friendly. By optimizing fuel usage and preventing unnecessary repairs, Eagle-IoT contributes to a more environmentally conscious operation.

- Improved Regulatory Compliance: Certain industries have regulations regarding generator maintenance and emissions. Eagle-IoT’s detailed reporting and data analysis can assist facilities in demonstrating compliance with these regulations.

Investing in Peace of Mind

Ultimately, Eagle-IoT offers more than just a generator monitoring solution. It provides peace of mind. By empowering facilities to take control of their generator health, Eagle-IoT fosters a more reliable and predictable operational environment. This allows facility managers to focus on their core business activities, confident in the knowledge that their generators are operating at peak performance.

The Future of Industrial Operations: A Connected Ecosystem

As the Industrial Internet of Things (IIoT) gains traction within industry, Eagle-IoT positions itself as a key player in this growing connected ecosystem. Their platform boasts the ability to integrate with various industrial equipment. This allows for the comprehensive analysis of data from multiple sources, ultimately leading to optimized overall operations. Imagine a future where Eagle-IoT not only monitors generators but also seamlessly interacts with production lines. This would create a smooth flow of information, enabling further efficiency gains.

By implementing Eagle-IoT, you’re not just acquiring a generator monitoring solution; you’re making an investment in the future of industrial operations. This future promises to be characterized by reliability, efficiency, and sustainability.