Running a fleet, whether for deliveries, taxis, or construction crews, can be a logistical maze. Streamlining operations translates directly to a healthier bottom line.

In this article we present a strategic framework that utilizes logical reasoning at every step. This approach, encompassing needs assessment, objective setting, data analysis, data-driven changes, meticulous monitoring, and continuous adaptation, transforms your fleet from simply functional to a well-oiled machine driving organizational success.

Needs Assessment & Objective Setting

The key to a successful fleet operation lies in a thorough assessment, and logical reasoning takes center stage in assessment. By analyzing your current landscape, you can identify problems and set well-defined objectives.

Identifying Operational Inefficiencies:

Don’t rely solely on intuition. Apply logical reasoning to pinpoint areas for improvement. Are fuel costs steadily rising? Do deliveries consistently fall behind schedule? Are maintenance schedules haphazard and reactive? These are all indicators that optimization is necessary.

Setting SMART Objectives:

Once you’ve identified problematic areas, use logic to translate them into achievable goals. SMART objectives are Specific, Measurable, Achievable, Relevant, and Time-bound. For example, instead of simply stating “reduce fuel costs,” a more logical and actionable objective would be “Reduce fuel consumption by 10% within the next six months.” This clear objective allows you to track progress and measure success with greater precision.

Gathering Intelligence – Data Analysis

Data is powerful, but only when it’s relevant. For effective decision-making, focus on collecting targeted information that sheds light on your specific goals. The focused approach allows you to extract valuable insights that optimize your fleet operations.

Targeted Data Collection:

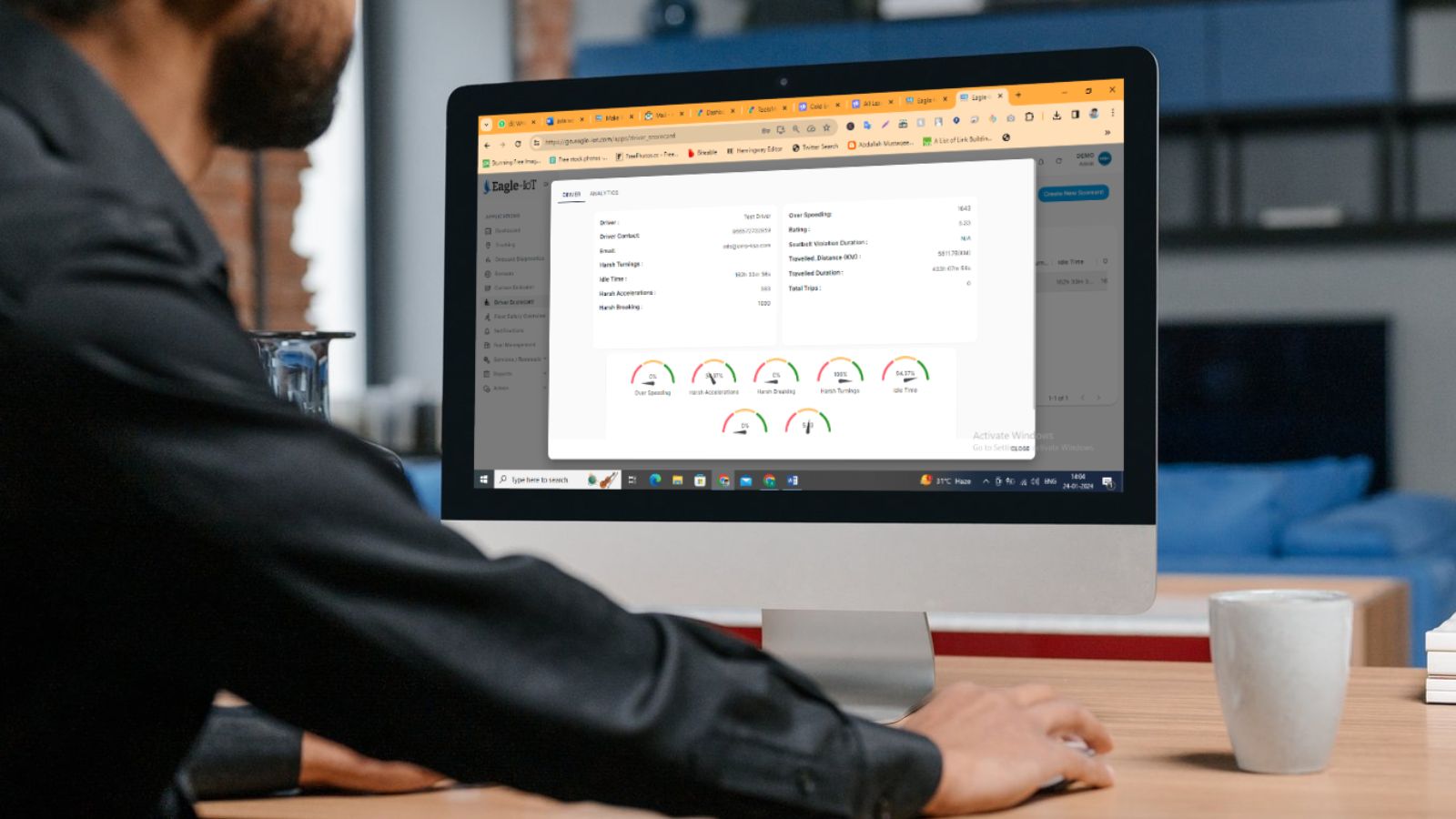

Avoid getting bogged down by information overload. Logically determine what data is crucial to achieving your objectives. Fuel usage per vehicle, delivery times, maintenance records, and driver performance metrics are all valuable data points depending on your specific goals.

Identifying Trends and Patterns:

The data holds the key, but logical analysis is the decoder ring that unlocks its secrets. Look for patterns and correlations within the data. For instance, a spike in fuel consumption for a specific vehicle might point towards a mechanical issue or inefficient driving habits. Identifying these trends allows you to address the root cause of the problem and improve overall efficiency.

Taking Action – Implementation of Data-Driven Changes

Now that you have a clear understanding of your challenges and the data to back it up, it’s time to take concrete action. Logical reasoning will guide you in developing and prioritizing solutions that make the most sense for your specific situation.

- Developing Data-Driven Solutions: Always base solutions on the data you’ve analyzed. For example, if you’ve identified a pattern of late deliveries due to inefficient routes, the logical solution would be to implement route optimization software or strategies. Similarly, if fuel consumption is high, training drivers on fuel-efficient practices and identifying vehicles with mechanical problems are logical next steps.

- Prioritization of Actions: Not all changes are created equal. Use logic to prioritize your actions based on their potential impact and feasibility. Fixing a faulty engine that’s guzzling gas might be more impactful than a minor tweak to a single route. By logically prioritizing, you can maximize the return on your investment of resources and time.

Measuring Progress – Monitoring and Evaluation

Change doesn’t happen overnight, and neither do results. This step requires consistent monitoring and logical evaluation of the impact of your implemented changes.

- Tracking Progress Towards Objectives: Remember those SMART objectives you defined earlier? Here’s where they come into play. Track your progress systematically towards achieving those goals. Are you on track to reduce fuel consumption by 10% within the six-month timeframe? Are deliveries happening more consistently on time? Logical monitoring helps you identify areas where progress is evident and areas that might need further adjustments.

Evaluating Effectiveness of Implemented Changes: Don’t be afraid to course-correct as needed. Use logic to assess the effectiveness of the implemented changes. Did fuel consumption truly decrease after training drivers and fixing faulty engines? Analyze the data to confirm or disprove your assumptions. This ongoing evaluation allows for continuous improvement and ensures your strategies remain optimized.

Learning from Results: Continuous Improvement Through Adaptation

The road to success is paved with continuous learning and adaptation. This final step ensures you’re constantly evolving and optimizing your fleet operations. It’s here that the rubber meets the road – the insights you gather from your implemented strategies become the fuel for further improvement.

Embrace the Power of Analysis: Don’t just celebrate successes or lament failures; analyze why a strategy worked or failed. Did route optimization lead to a significant decrease in delivery times? Did driver training on fuel-efficient practices translate to a measurable reduction in fuel consumption? Analyze the data to pinpoint the cause-and-effect relationships.

Identify Areas for Refinement: This analysis will reveal areas where your strategies can be further refined. Perhaps a specific route needs minor tweaks, or perhaps a different training approach would yield even better results for fuel efficiency. By understanding the “why” behind your results, you can make targeted adjustments for continuous improvement.

Embrace a Culture of Experimentation: Don’t be afraid to experiment with new strategies. A/B testing different routes or maintenance schedules can provide valuable insights. Remember, even unsuccessful experiments offer valuable lessons.

The Cycle Continues

As you learn and adapt, the cycle starts anew. Revisit your needs assessment to see if your objectives need refinement based on your evolving understanding of your fleet’s operations. This continuous loop of logical reasoning, data-driven decision making, and adaptation ensures your fleet remains optimized for long-term success. evolving understanding of your fleet’s operations. This continuous loop of logical reasoning, data-driven decision making, and adaptation ensures your fleet remains optimized for long-term success.