Balancing fluctuating consumer preferences and potential supply chain disruptions is crucial for businesses to thrive. Maintaining optimal inventory levels prevents stockouts and ensures readiness to capitalize on market opportunities. Given that inventory is a substantial investment, effective management is vital for boosting profitability, enhancing customer satisfaction, and streamlining operations.

This comprehensive article delves into the world of inventory management, exploring best practices for streamlining processes, achieving a strategic advantage, and navigating the ever-evolving landscape of business.

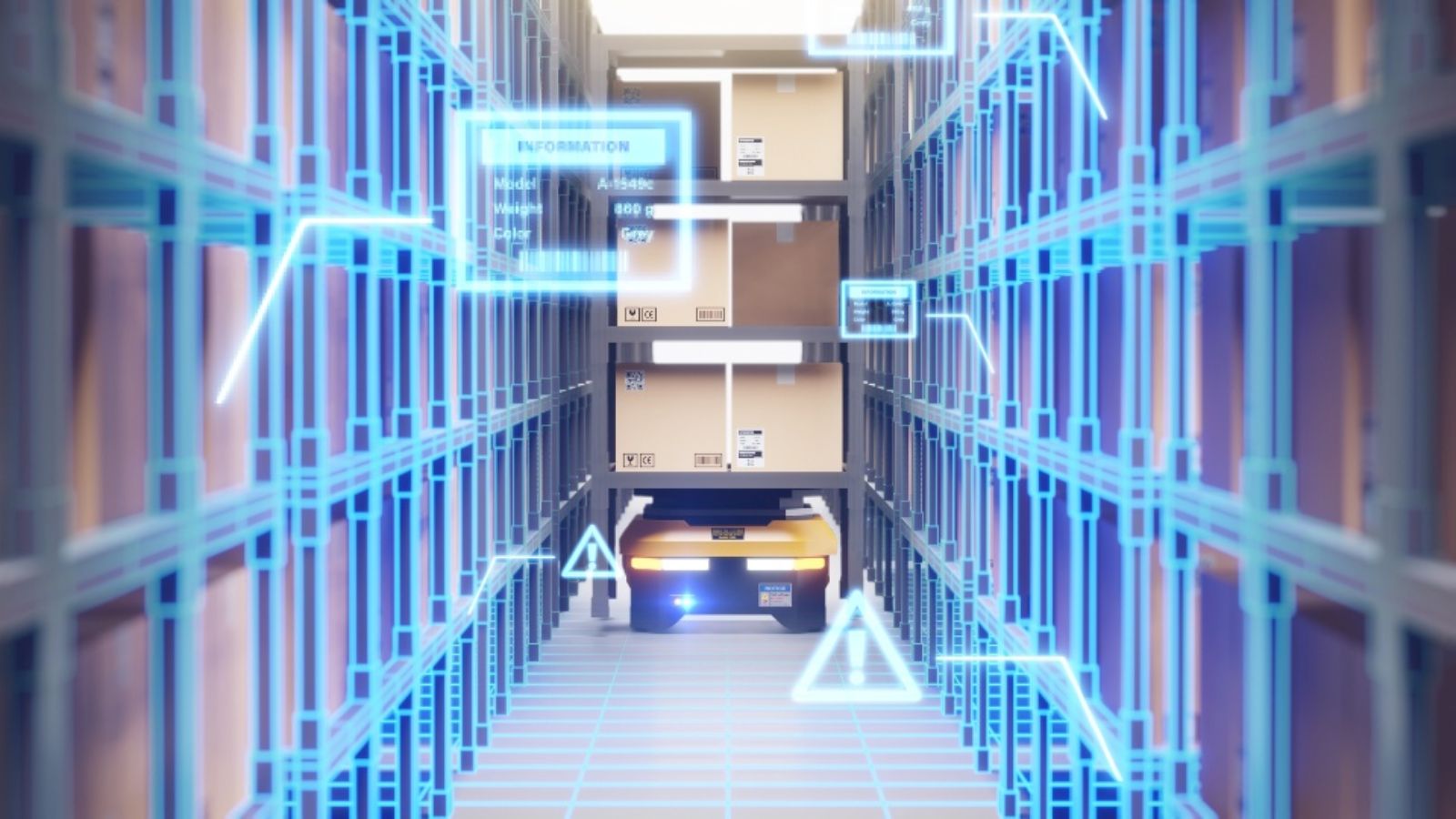

The Evolving Landscape of Inventory Management

Traditionally, inventory management focused on maintaining physical stock levels through manual processes and record-keeping. However, the rise of e-commerce, globalization, and just-in-time (JIT) manufacturing necessitates a more sophisticated approach. Businesses now contend with:

Increased Product Complexity: Modern products often involve intricate components and require precise inventory management strategies for each part.

Global Supply Chains: Complex global supply chains introduce variables like extended lead times and potential disruptions due to geopolitical or economic factors.

Shifting Consumer Demands: Consumer preferences can change quickly, requiring businesses to adapt their inventory levels to meet evolving market trends.

Data-Driven Decision Making: The availability of vast amounts of data necessitates leveraging analytics to make informed decisions about procurement, forecasting, and stock levels.

The Significance of Strategic Inventory Management

Beyond simply keeping track of stock, strategic inventory management encompasses a comprehensive set of practices that consider all aspects of the inventory lifecycle, from forecasting demand to optimizing storage and controlling stock levels. Here’s how proactive inventory management benefits businesses:

Enhanced Profitability: By minimizing stockouts and reducing excess inventory carrying costs (warehousing, insurance, etc.), businesses can maximize profit margins. Efficient inventory allocation ensures capital is readily available for investments that drive growth and innovation.

Improved Customer Satisfaction: Unfulfilled orders due to stock shortages can severely damage customer experience. Effective inventory management ensures products are readily available, fostering customer loyalty and repeat business. Satisfied customers are more likely to become brand advocates, driving organic growth through positive word-of- mouth marketing.

Strategies for Effective Inventory Management: A Multi-Pronged Approach

Implementing proven strategies can transform inventory management from a reactive function to a proactive driver of business success. Here’s a detailed exploration of key considerations:

Demand Forecasting: Utilize data analytics to predict future demand based on historical sales data, industry trends, marketing initiatives, and seasonality. Accurate forecasting allows for proactive purchasing, prevents stockouts, and avoids overstocking slow-moving items. Consider employing various forecasting techniques, such as moving averages, exponential smoothing, and machine learning algorithms, for greater accuracy.

ABC Analysis: Categorize inventory items based on their value and criticality (annual dollar usage). The ABC analysis classifies items into three categories:

A Items (High Value, High Criticality): These items represent a significant portion of the total inventory value and require the most stringent controls. Implement frequent cycle counting for A items, maintain safety stock levels to avoid stockouts, and negotiate favorable terms with suppliers.

B Items (Moderate Value, Moderate Criticality): These items require a balance between control and efficiency. Implement periodic cycle counting for B items and explore vendor-managed inventory (VMI) programs where suppliers manage stock levels based on pre-determined agreements.

C Items (Low Value, Low Criticality): These items represent a small portion of the total inventory value and require less stringent controls. Implement less frequent cycle counting for C items and consider bulk purchasing to leverage economies of scale.

Minimum Order Quantity Optimization:

Negotiate Minimum Order Quantities (MOQs) with suppliers to strike a balance between cost efficiencies and avoiding overstocking slow-moving items. Explore alternative solutions like vendor-managed inventory (VMI) programs or consignment inventory models where suppliers retain ownership of the stock until it’s sold.

Warehouse Optimization:

Designate efficient warehouse layouts to minimize travel time for picking and packing processes. Utilize effective storage solutions like vertical racking systems to maximize space utilization. Implement a clear and consistent labeling system for easy identification and location of inventory items.

Seamless Integration of Asset Management & Inventory Management

Effective inventory management goes beyond just tracking physical goods. It’s a comprehensive system that encompasses the entire lifecycle of an asset, from its procurement to its final disposal. Eagle-IoT Inventory Management offers insights into two crucial aspects of Asset MManagement: Asset Procurement and Asset Assignment Management.

Asset Procurement: Recording and Capitalization

Recording at Receipt or Capitalization: Organizations typically record assets when they are physically received or when they meet specific capitalization criteria as defined by their tracking policy. This ensures proper financial accounting and allows for depreciation calculations.

ERP and Procurement Software Integration: Modern businesses leverage Enterprise Resource Planning (ERP) or dedicated procurement software for streamlined asset procurement. These systems can automatically generate asset records upon receiving confirmation or when an asset meets capitalization criteria. This integration eliminates manual data entry and reduces the risk of errors.

Asset Assignment Management: Tracking and Maintaining Control

Effective asset assignment management ensures complete visibility over the location, usage, and condition of all assets. Here’s how organizations achieve this:

Multifunctional Handheld Scanners: These scanners allow employees to quickly and accurately track assets, update their location data, and record maintenance activities. This real-time data collection ensures a clear understanding of where each asset is deployed.

Integration with Location Data Sources: Integrating asset management systems with location tracking tools like GPS or RFID technology provides even greater visibility. This allows for real-time monitoring of high-value assets or those critical for operations.

Audit Trail and Documentation: Maintaining a comprehensive audit trail for all asset movements and associated approvals is essential. This includes recording personnel responsible for assignments, dates of transfer, and any relevant maintenance documentation. This audit trail facilitates accountability and helps identify potential issues with asset usage.

Connecting Asset Management with Inventory Management:

By integrating asset management with inventory management processes, organizations can achieve a holistic view of their resources. This combined approach offers several benefits:

Improved Asset Utilization: Real-time asset data helps identify underutilized assets, allowing for re-deployment to optimize resource allocation.

Reduced Loss and Theft: Robust tracking systems deter asset theft and minimize loss through accidental misplacement.

Efficient Maintenance Scheduling: Maintenance history data within the asset management system facilitates preventative maintenance scheduling, reducing downtime and extending asset lifespan.

Streamlined Procurement Decisions: Data on asset usage and lifecycle helps with informed procurement decisions. Insights into asset performance can guide purchases of replacements or upgrades.

A Unified Approach for Business Efficiency

Implementing a synergistic approach that integrates asset procurement, assignment management, and inventory management empowers businesses to:

Optimize Resource Utilization: Gain complete visibility and control over both physical inventory and fixed assets, ensuring they are used efficiently and effectively.

Enhance Financial Control: Accurate asset records and depreciation calculations contribute to improved financial reporting and compliance.

Reduce Operational Costs: Minimize losses, optimize maintenance schedules, and make data-driven procurement decisions to streamline operations and reduce costs.

By integrating these practices into their overall business strategy, companies can achieve a competitive edge through efficient resource management and responsible asset lifecycles.

Eagle-IoT Inventory Management provides a robust platform for integrating asset and inventory management, offering features such as real-time tracking, automated data collection, and advanced analytics. By leveraging Eagle-IoT, businesses can gain valuable insights, optimize operations, and make data-driven decisions to drive growth and profitability.

If you want to learn more about Eagle-IoT