SFDA Mandate: Electronic Cold Chain Monitoring Now Mandatory in Saudi Arabia

In a landmark move to safeguard public health and enhance food quality, the Saudi Food and Drug Authority (SFDA) has issued a mandatory directive: All refrigerated and frozen food facilities—including factories, warehouses, and transport vehicles—must electronically link their temperature and humidity monitoring systems to the SFDA’s designated platform, “Wasl.”

This regulatory step is not just a guideline—it’s a binding obligation for businesses in the food cold chain to transition from manual logs and isolated monitoring to a fully connected, transparent, and accountable cold chain infrastructure.

Why SFDA Is Raising the Bar?

The SFDA’s mandate is a proactive response to recurring gaps in cold chain safety. Historically, the sector has struggled with:

- Missed temperature deviations due to manual or delayed monitoring

- Inadequate data retention for audits and accountability

- Inconsistent sensor placements leading to inaccurate readings

- Limited visibility into product conditions during transport

These issues increase the risk of product spoilage, regulatory penalties, and public health hazards. To counter this, the SFDA now demands real-time electronic monitoring, reliable data logging, and precise sensor calibration as part of nationwide compliance enforcement.

Who is Affected and What’s Required?

This mandate specifically targets facilities and vehicles involved in the storage and transport of meat, poultry, and fish. Key requirements include:

- Refrigerated and frozen food manufacturers

- Cold storage warehouses

- Transport fleets for meat, poultry, and seafood

- Electronic Linking to “Wasl” Platform: All temperature and humidity measurement devices must be electronically connected to the SFDA’s “Wasl platform”.

- Continuous Recording: Refrigeration and freezing warehouse rooms, along with transportation units, must be equipped with recorders for continuous temperature and humidity monitoring.

- Data Retention: The recorded data must be preserved for a period exceeding the product’s shelf life or for a specified duration determined by relevant authorities for future reference.

- Accurate Sensor Placement & Calibration: Temperature sensors must be strategically installed at various locations and heights, guided by an effective thermal map, to ensure readings accurately represent the storage and transportation area. These sensors must also be periodically calibrated and monitored.

The Solution: Seamless Compliance with Eagle-IoT

Eagle-IoT by DMS is proud to be an SFDA-approved service provider, delivering next-generation cold chain monitoring tools that make compliance not only possible—but painless.

Our Cold Chain Monitoring Solution is built to fully support the SFDA’s Wasl platform integration, combining real-time monitoring, automated data logging, and actionable insights in one powerful, scalable system.

SFDA Mandate: Electronic Cold Chain Monitoring Becomes Mandatory in Saudi Arabia

The Saudi Food & Drug Authority (SFDA) is stepping up its commitment to consumer safety and food quality. A recent circular from the SFDA makes it mandatory for all refrigerated and frozen food factories, warehouses, and their associated transportation means to electronically link their temperature and humidity monitoring systems with the SFDA’s designated platform, “Wasl”. This directive marks a significant move towards a more transparent, secure, and technologically advanced cold chain in the Kingdom.

Why This Mandate? Enhancing Food Safety and Public Health

The SFDA’s decision stems from a proactive approach to mitigate potential food safety risks throughout the entire supply chain. By leveraging Internet of Things (IoT) technology, the Authority aims to significantly enhance compliance with stringent transportation and storage requirements. This initiative aligns with the SFDA’s core mission to ensure the quality and safety of food in the Kingdom, as stipulated by various Royal Decrees and technical regulations.

Who is Affected and What’s Required?

This mandate specifically targets facilities and vehicles involved in the storage and transport of meat, poultry, and fish. Key requirements include:

- Electronic Linking to “Wasl” Platform: All temperature and humidity measurement devices must be electronically connected to the SFDA’s “Wasl platform”.

- Continuous Recording: Refrigeration and freezing warehouse rooms, along with transportation units, must be equipped with recorders for continuous temperature and humidity monitoring.

- Data Retention: The recorded data must be preserved for a period exceeding the product’s shelf life or for a specified duration determined by relevant authorities for future reference.

- Accurate Sensor Placement & Calibration: Temperature sensors must be strategically installed at various locations and heights, guided by an effective thermal map, to ensure readings accurately represent the storage and transportation area. These sensors must also be periodically calibrated and monitored.

How to Ensure Compliance: Partnering for Seamless Integration?

Eagle-IoT is proud to be an approved and qualified service provider by the SFDA, offering robust cold chain monitoring solutions designed to meet and exceed these regulatory demands.

Eagle-IoT’s SFDA-Compliant Cold Chain Monitoring Solution: Beyond Compliance

As your trusted cold chain technology partner, Eagle-IoT empowers you to meet SFDA’s strict temperature control regulations with real-time visibility, secure data logging, and automated compliance tools. Our solution is purpose-built to help you protect quality, avoid penalties, and stay ahead.

Key Capabilities of Eagle-IoT’s Cold Chain Solution

|

Feature |

Benefit |

|

Temperature & Humidity Monitoring |

High-precision wireless sensors for all cold environments |

|

Thermal Mapping |

Ensure accurate sensor placement across rooms and transport units |

|

Door Open Alerts |

Instantly detect breaches in storage integrity |

|

Water Leakage Detection |

Prevent structural damage and protect inventory |

|

LoRaWAN, Wi-Fi, BLE Sensors |

Flexible, energy-efficient installation in any facility or vehicle |

|

Real-Time Cloud Platform |

Monitor conditions remotely with live dashboards and alerts |

|

Automated Data Logging |

SFDA-compliant logs with 1–3 year retention for audit readiness |

|

SMS, WhatsApp, Email Alerts |

Take immediate action on any deviation, 24/7 |

|

Custom Reports & Analytics |

Generate visual reports for operations, audits, and regulatory submissions |

Beyond just compliance, Eagle-IoT delivers additional benefits that enhance your entire operation:

- Reduced Product Spoilage and Waste: Proactively identify and prevent temperature excursions that can lead to costly product loss.

- Optimized Energy Consumption: Gain insights into cooling unit performance to identify inefficiencies and reduce energy bills.

- Improved Operational Efficiency: Streamline monitoring processes and reduce manual checks, freeing up staff for other critical tasks.

- Enhanced Audit Readiness: Easily retrieve and present comprehensive, compliant data, significantly simplifying SFDA audits.

- Proactive Maintenance: Detect potential equipment malfunctions early, allowing for preventive maintenance and avoiding costly breakdowns.

- Increased Customer Trust: Provide documented proof of proper cold chain handling, building confidence with your clients and end-consumers.

- Competitive Advantage: Differentiate your business by demonstrating a commitment to advanced technology and the highest standards of food safety.

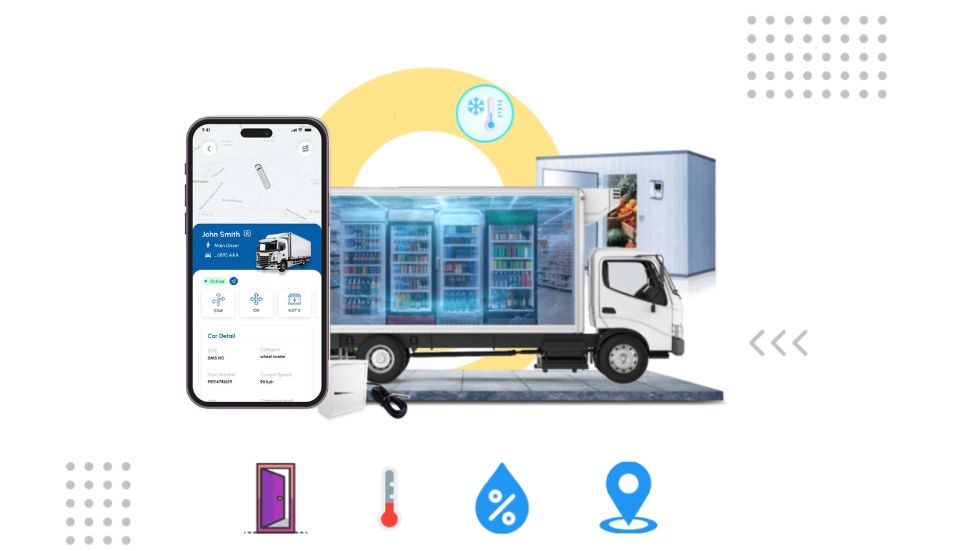

Stay Connected with the Eagle-IoT Mobile App

Take your cold chain with you—anytime, anywhere.

- Real-time temperature readings

- Instant alerts

- Historical logs

- Compliance dashboards

All from your smartphone.

Deadline Alert: October 01, 2025

All affected establishments must complete the electronic Wasl platform integration by October 01, 2025. This provides a clear timeframe for businesses to assess their current systems and implement the necessary upgrades or partnerships.

Prepare Your Cold Chain for the Future, Today

The SFDA’s mandate is a clear signal: robust, electronically linked cold chain monitoring is no longer a best practice—it’s a legal obligation. Businesses operating in the refrigerated and frozen food sector in Saudi Arabia must act now to ensure their compliance before the deadline. Partnering with an SFDA-approved provider like Eagle-IoT not only helps you avoid penalties but also elevates your operational efficiency and commitment to consumer safety.

Ready to Get Started?

Book your free compliance consultation today and let our experts show you how Eagle-IoT can simplify your SFDA transition.