Navigating the Diesel Price Hike in Saudi Arabia: Strategies for Fleet Managers

The recent domestic diesel price increase in Saudi Arabia, reaching SAR 1.66 per liter ($0.44/l) as of January 1st, represents a 44% hike. This significant price adjustment has had a considerable impact on the transportation and logistics sector, presenting a significant challenge for businesses heavily reliant on efficient and cost-effective fleet operations.

Almarai Co., a leading dairy producer in the region, has publicly disclosed the impact of this price increase. In a statement to Tadawul, the Saudi Stock Exchange, Almarai estimated that the higher diesel prices will likely result in an increase in costs by approximately SAR 200 million in 2025.

This significant price increase underscores the critical need for businesses in the transportation and logistics sector to implement strategies to mitigate the impact of rising fuel costs and ensure long-term sustainability. This escalating fuel cost environment demands a proactive and data-driven approach to fleet management.

A comprehensive fuel monitoring solution offers a strategic advantage by providing real-time insights into fuel usage patterns, identifying areas for improvement, and ultimately enhancing operational efficiency and profitability.

Real-time Fuel Consumption Tracking

A cornerstone of effective fuel management, real-time fuel consumption tracking allows businesses to gain granular visibility into fuel usage patterns across their entire fleet. By continuously monitoring fuel levels and identifying anomalies such as sudden drops or unexpected increases, businesses can swiftly detect potential issues like fuel theft, mechanical problems, or driver misconduct. This proactive approach enables prompt intervention, minimizing losses and ensuring the integrity of fuel resources.

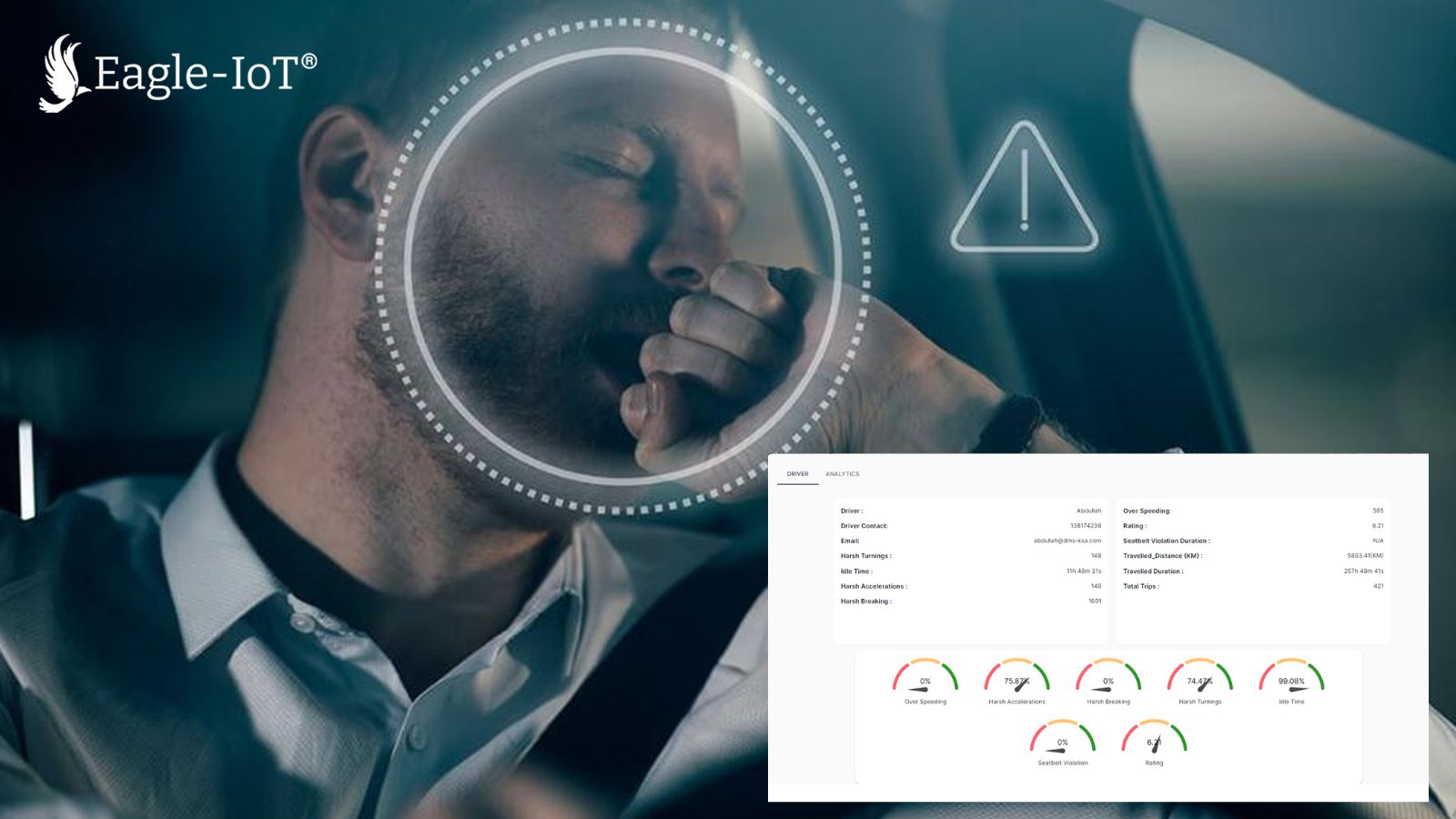

Driver Behavior Analysis: A Key to Fuel Efficiency

Aggressive driving habits, such as rapid acceleration, hard braking, and excessive idling, significantly impact fuel consumption and contribute to increased wear and tear on vehicles. A comprehensive fuel monitoring solution can capture and analyze driver behavior data, identifying patterns that contribute to higher fuel usage. This data-driven approach allows businesses to:

- Implement targeted training programs: Develop and deliver customized training programs to educate drivers on fuel-efficient driving techniques, emphasizing smooth acceleration, gradual braking, and minimizing idling time.

- Provide personalized feedback: Offer individualized feedback to drivers based on their driving behavior, highlighting areas for improvement and recognizing safe and fuel-efficient driving practices.

- Promote a culture of safety and efficiency: Foster a culture of safe and responsible driving within the organization, encouraging drivers to prioritize fuel efficiency and minimize their environmental impact.

Proactive Maintenance and Vehicle Health

Proactive vehicle maintenance is crucial for optimal fuel efficiency. By continuously monitoring key vehicle performance indicators, such as engine health, tire pressure, and emissions levels, fuel monitoring systems can predict potential issues before they escalate into major breakdowns.

- Preventive maintenance scheduling: Enables timely preventative maintenance, minimizing downtime and ensuring vehicles operate at peak efficiency.

- Reduced fuel wastage: Minimizes fuel wastage caused by mechanical issues such as engine misfires, clogged filters, and underinflated tires.

- Improved vehicle lifespan: Proactive maintenance extends the lifespan of vehicles, reducing the need for frequent replacements and associated costs.

-

Route Optimization and Scheduling

Integrating fuel monitoring data with advanced route planning software such as Eagle-IoT enables businesses to optimize delivery routes, minimizing unnecessary mileage and fuel consumption. By considering real-time traffic conditions, road closures, and delivery schedules, the system can identify the most efficient routes, reducing travel time and fuel costs while ensuring timely deliveries.

Beyond Cost Savings: Enhancing Overall Business Performance

The benefits of a comprehensive fuel monitoring solution extend beyond immediate cost savings. By optimizing fleet operations and enhancing driver safety, businesses can:

- Improve customer satisfaction: Consistent and timely deliveries enhance customer satisfaction and build strong customer relationships.

-

- Enhance brand image: Demonstrating a commitment to sustainability and efficient operations can enhance the company’s image and reputation.

- Improve driver morale: By promoting safe driving practices and recognizing fuel-efficient driving behaviors, businesses can improve driver morale and reduce driver turnover.

- Gain a Competitive Edge: Businesses that effectively manage fuel costs and optimize their fleet operations will gain a significant competitive advantage.

-

Rising diesel prices present a formidable challenge, but they also offer an opportunity to rethink and optimize fleet operations. By embracing a data-driven approach to fleet management and leveraging the power of advanced fuel monitoring solutions, businesses can navigate this challenging environment successfully.

By optimizing fuel consumption, enhancing driver safety, and streamlining operations, businesses can mitigate the impact of rising fuel costs, improve profitability, and ensure long-term sustainability. Investing in a comprehensive fuel monitoring solution is not merely a cost-saving measure; it is a strategic investment in the future of the business.

- Contact us today for a personalized consultation and discover how our fuel monitoring solutions can transform your business operations. Together, we can navigate the challenges of rising fuel costs and achieve sustainable growth.