Axle weights, distribution and their configuration

Knowing axle weights and their distribution and configuration is fundamental in the trucking industry.

Trailer weight distribution is critical while moving goods over long and distances. Similarly, knowing the tractor trailer axle weights is essential for ensuring that a load is hauled legally. Driving with a trailer is substantially distinct from everyday driving.

It is of foremost importance to mention that Eagle-IoT offers axle load monitoring solution for various axle arrangements with diverse axle configurations under the license of the Transport General Authority (TGA) and connects your trucks and trailer to the WASL portal where the operation card is issued. As we all know, an operation card is essential in KSA for your heavy vehicle transport to haul loads on roads. Some of the configurations are mentioned below:

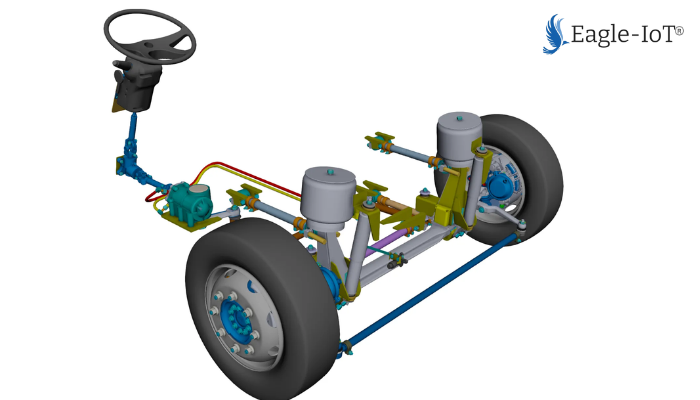

Steering Axle Configurations

The foremost axle is used to steers the tractor.

Single Axle

It is generally seen on a smaller tractor-trailer, a spread axle trailer, or as a booster.

Tandem

This is the most popular tractor trailer axle design configuration. There is usually a driving tandem and a trailer tandem.

Tri-Axle

An assortment of three axles that can be found on vehicles, trailers, or both.

Quad-Axle

A set of four axles can be found on trailers.

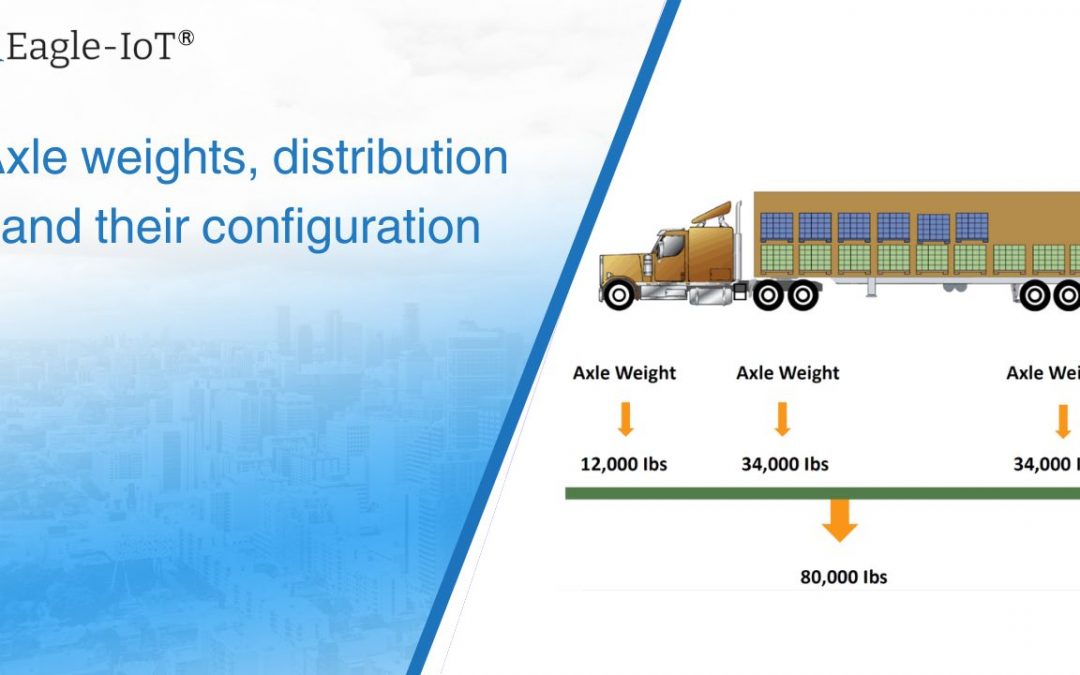

Weight distribution

Weight distribution is defined as the amount of total load capacity placed on the ground at an axle, set of axles, or individual wheel. In order to adhere to the axle ratings and weight laws, the weight of a vehicle must be spread on the axles specified by the chassis manufacturer. The axle capacity or legal weight constraints, whichever is lower, limit axle capacity. Besides the axle capacity, the Gross Vehicle Mass (GVM) is referred as the maximum operational weight of the vehicle specified by the manufacturer, which incorporates the cab and chassis, engine, and every other component of the truck.

The distribution of load weight must be carefully considered to establish how much of the total, including chassis, cab, body, and payload, will be carried on the front axle and how much will be carried on the rear axle, and the total. A few inches forward or backward movement of the components on the chassis can do the trick to adequate weight distribution for the vehicle.

Aside from being illegal, improper weight distribution and overloading cause excessive wear, untimely malfunction of parts leading to risky operation such as vulnerable directional control and inadequate braking capacity, and increased strain that may contribute to the frame cracking or breaking.

Whether your vehicle has a spring-leaf axle or a pneumatic axle, Eagle-IoT offers a reliable solution for both.

Eagle-IoT offers a high-tech sensor for spring leaf axles, which is installed on the differential axle to monitor the change in height of that axle as the weight increases. For pneumatic axles, the pressure sensor is installed to measure the air in the axle balloons which increases as the weight on the axle increases.

A trip report can be generated based on exact time and location, providing you access to monitor where and how much the weight changed to reveal underhand cargo. Besides the Axle Load Monitoring Solution, Eagle-IoT offers a comprehensive solution for Trailer GPS Tracking and weight Tracking, and Trailer fuel management solution.

To know more about us, Contact us