The transportation and logistics industry is continuously evolving, with technological innovations playing a central role in shaping its future. Among these innovations, powered trailers equipped with telematics systems stand out as game-changers, offering unprecedented levels of operational efficiency, asset management, and cost savings. The fusion of powered trailers and telematics—especially when integrated with advanced fleet management platforms like Eagle-IoT—promises to revolutionize how companies manage their fleets.

The Rise of Powered Trailers

Traditionally, trailers have been passive assets in the supply chain. They were towed by powered vehicles, but lacked any independent power source or data collection capability. However, with the advent of powered trailers, this is changing. Powered trailers are trailers that have their own onboard energy systems, often derived from solar panels, batteries, or auxiliary power units (APUs). This onboard power enables trailers to support a range of sensors and devices, turning them into intelligent assets capable of real-time data collection and communication.

This shift transforms trailers from passive carriers into active participants in the fleet ecosystem, capable of contributing valuable data for better decision-making. Coupled with telematics, powered trailers open up a world of possibilities in fleet management, offering improved visibility, efficiency, and safety.

Key Benefits of Telematics in Powered Trailers:

Real-Time Location Tracking: With telematics, powered trailers can be tracked in real time, giving fleet managers complete visibility over their assets. Whether the trailer is in transit or parked at a depot, managers can know its exact location at any time. This improves asset security and helps

optimize logistics by ensuring trailers are where they need to be, reducing downtime and maximizing productivity.

Enhanced Asset Utilization: Telematics systems offer detailed data on how and when trailers are being used. With powered trailers, sensors can monitor factors such as load weight, door openings, and temperature. This data helps fleet managers ensure trailers are utilized to their full potential, avoiding instances of underutilization or overloading, which can lead to unnecessary wear and tear or regulatory violations.

Preventive Maintenance: The onboard power systems in powered trailers allow telematics to monitor key components in real time. Sensors can track brake wear, tire pressure, suspension systems, and more. When integrated with a fleet management platform like Eagle-IoT, this data can be analyzed to predict maintenance needs before they lead to costly breakdowns. Preventive maintenance reduces unplanned downtime, extends the life of assets, and lowers overall maintenance costs.

Cold Chain Management:

For industries reliant on temperature-sensitive cargo, such as pharmaceuticals or perishable goods, powered trailers equipped with temperature sensors are essential. Telematics systems can monitor and report real-time temperature data, ensuring that cold chain conditions are maintained throughout the journey. If the temperature falls outside of acceptable ranges, immediate alerts can be sent to fleet managers, enabling corrective action to prevent spoilage or damage.

Energy Efficiency:

Powered trailers often rely on renewable energy sources such as solar panels or regenerative braking systems. Telematics data from these systems can be used to monitor energy consumption and generation, ensuring that the trailers operate at optimal efficiency. This can lead to significant fuel savings, reduced carbon emissions, and a lower environmental impact for fleets

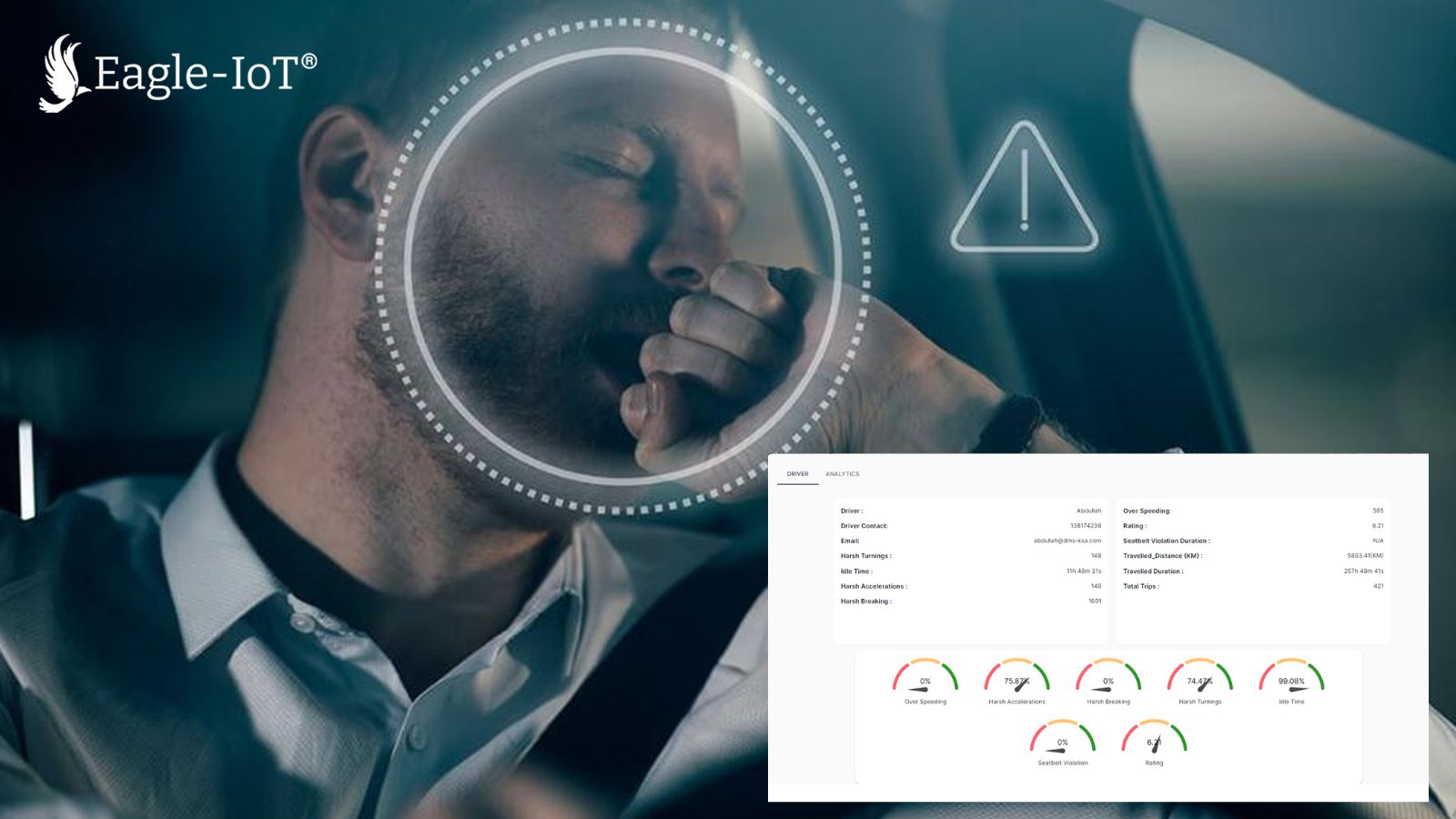

Driver Behavior Monitoring:

While trailers themselves do not have drivers, the data collected from powered trailers can be used in conjunction with telematics systems in the towing vehicles to assess driver behavior. For example, telematics can track harsh braking, sudden acceleration, or excessive idling, all of which can impact trailer wear and tear. By addressing unsafe or inefficient driving practices, fleet managers can improve safety, reduce operational costs, and extend the lifespan of their assets.

Comprehensive Asset Monitoring:

Eagle-IoT integrates with powered trailers to provide a single dashboard for monitoring all assets, from powered vehicles to trailers. This allows for real-time tracking of trailers, including their location, usage, and condition. Managers can view data such as temperature, load weight, and energy consumption all in one place, simplifying fleet oversight and reducing the need for manual inspections.

Predictive Maintenance Alerts:

By analyzing data collected from powered trailers, Eagle-IoT can generate predictive maintenance alerts. These alerts notify fleet managers when critical components like brakes or tires are approaching failure, enabling them to schedule repairs before a breakdown occurs. This reduces the likelihood of costly downtime and ensures trailers remain in optimal condition.

Geofencing Capabilities:

Eagle-IoT’s geofencing feature allows fleet managers to create virtual boundaries for powered trailers. When a trailer enters or exits a designated zone, the system automatically triggers alerts, enhancing asset security and ensuring compliance with operational protocols. For example, trailers can be restricted to specific routes, and deviations can be flagged in real time.

Custom Reporting and Analytics: One of Eagle-IoT’s standout features is its ability to generate customized reports based on the specific needs of the fleet. Whether you’re looking for insights into fuel consumption, energy efficiency, asset utilization, or driver behavior, Eagle-IoT can generate reports that provide actionable insights. For powered trailers, these reports can be tailored to include data on energy usage, maintenance schedules, and temperature control, helping fleet managers optimize performance.

Challenges and Considerations

Powered trailers, when combined with advanced telematics systems and platforms like Eagle-IoT, represent a significant leap forward in fleet management. They offer fleet managers unprecedented levels of control, visibility, and efficiency, transforming trailers from passive assets into integral components of a data-driven, optimized fleet. By harnessing the full power of this technology, companies can reduce costs, improve operational efficiency, and enhance safety—ensuring they stay competitive in an increasingly complex logistics landscape.

While it offers numerous benefits, there are challenges that fleet managers need to consider. These include the upfront costs of implementing powered trailers and telematics systems, as well as the need for ongoing maintenance and training to ensure the technology is used effectively.

Additionally, not all powered trailers are created equal, and the type of power system (e.g., solar panels, APUs) and telematics technology chosen can impact the performance and return on investment. It’s crucial for fleet managers to evaluate their specific needs and work with trusted providers like Eagle-IoT to ensure they are leveraging the right technology for their operations.