How IoT Solutions Can Empower Modern Cold Storage Today

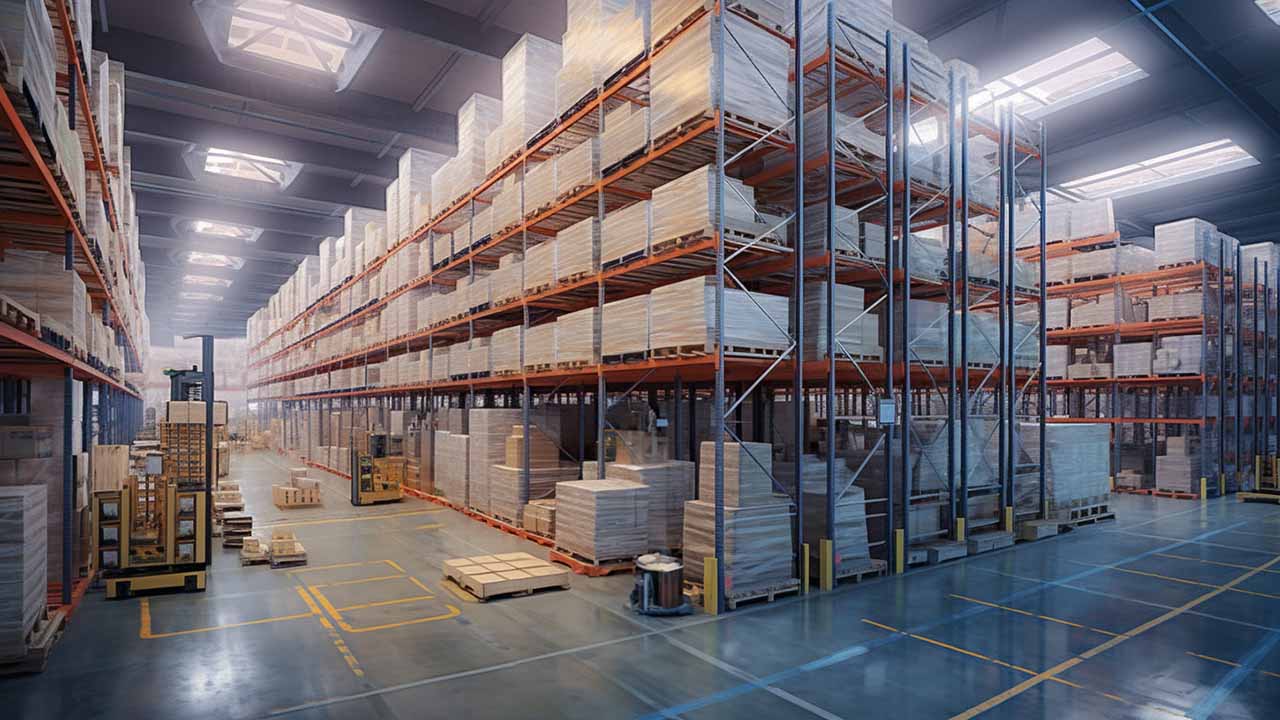

Within the intricate network of the global supply chain, cold storage facilities play a vital role. These specialized warehouses ensure the safekeeping and distribution of temperature-sensitive products, ranging from perishables like fruits and vegetables to pharmaceuticals requiring stringent storage conditions. However, managing a cold storage facility presents a unique set of challenges compared to traditional warehouses. Here, maintaining consistent temperatures, preventing spoilage, and maximizing space utilization are paramount concerns.

Despite being the cornerstone of a safe and efficient global food supply chain, cold storage facilities face several persistent challenges in their day-to-day operations. These challenges can significantly impact factors like product quality, operational efficiency, and overall profitability.

Here are some specific examples of the impact these challenges can have:

Addressing the Challenges in Cold Storage Facilities

Lack of Comprehensive Inventory Visibility:

Traditional paper-based inventory systems often struggle to keep pace with the dynamic environment of a cold storage facility. This can lead to inaccurate stock levels, misplaced items, and ultimately, the expiration of valuable inventory.

Consignment Damage:

The constant movement of goods in and out of cold storage increases the risk of damage. Without proper tracking mechanisms, identifying the source of damage and assigning accountability becomes a complex task.

Suboptimal Storage Utilization:

Cold storage facilities are inherently expensive to operate due to the specialized infrastructure required to maintain consistent low temperatures. Maximizing space utilization is crucial for profitability. However, manual space allocation methods often lead to wasted space or inefficient stacking arrangements.

Redundant Processes:

Repetitive tasks such as manual temperature checks, data entry, and reconciliation not only slow down operations but also increase the risk of human error.

Extended Turnaround Times for Picking and Packing:

Locating specific items within a vast, cold environment can be a time-consuming endeavor, leading to longer turnaround times for picking and packing orders.

The Rise of the Connected Cold Store: How IoT Empowers Efficiency

IoT, the network of interconnected devices sharing data, is rapidly transforming cold storage management. By integrating sensors, tags, and real-time data collection with warehouse management systems (WMS), IoT empowers facilities to address critical challenges and optimize operations.

Benefits of IoT Solutions for Warehouse Management:

- Reduced Warehouse Operating Costs: IoT sensors can monitor and optimize energy consumption by analyzing cooling system performance and identifying areas for improvement. Additionally, automated processes and reduced manual tasks contribute to lower labor costs.

- Effective, Real-time Tracking: Item-level tagging with RFID or barcode technology allows for real-time location tracking. This eliminates the need for manual searches, improves picking accuracy, and ensures first-in, first-out (FIFO) inventory management to minimize spoilage.

- Seamless Integration with Warehouse Management Systems (WMS): IoT data seamlessly integrates with WMS software, providing a holistic view of the entire cold chain process. This empowers data-driven decision making, allowing for optimized warehouse layout, improved picking routes, and automated replenishment.

- Enhanced Operational Efficiency: Automating tasks like temperature monitoring, data collection, and equipment maintenance frees up valuable staff time for more strategic activities. This streamlines operations and minimizes human error.

- Optimization of Location-Based Bin Allocation & Space Utilization: IoT-powered warehouse mapping tools such as Eagle-IoT offer real-time insights into space allocation. This data helps optimize storage layouts, prevent wasted space, and ensure efficient stacking practices.

Building a Smarter Cold Store with IoT

Here are some key steps to integrate IoT solutions into your cold storage facility:

Identify Pain Points: Begin by analyzing your current operational challenges and pinpoint areas where IoT can make the most significant impact.

Selecting the Right Solution: A variety of IoT solutions are available, including temperature sensors, RFID tags, and real-time location systems. Choose solutions that specifically address your identified needs.

Ensuring WMS Integration: Ensure seamless data flow by selecting IoT solutions compatible with your existing WMS platform.

Investing in Staff Training: Equipping your staff with the knowledge and skills to operate and utilize the new IoT system effectively is crucial for successful implementation.

The Future of Cold Storage: A Connected Ecosystem

The future of cold storage lies in a connected ecosystem where data flows seamlessly across the entire supply chain. Integrating IoT with other technologies like artificial intelligence (AI) will further enhance operational efficiency. AI-powered systems can analyze data to predict equipment failures, optimize stock levels, and even dynamically adjust temperatures for different product types.

By embracing IoT solutions, cold storage facilities can overcome traditional challenges, ensure product quality and safety, and gain a competitive edge in the ever-evolving food and logistics landscape. As the industry continues to adopt these technologies, we can expect a future where cold stores operate with unparalleled efficiency, minimizing waste and maximizing profitability.