Axle Load Monitoring

Solution

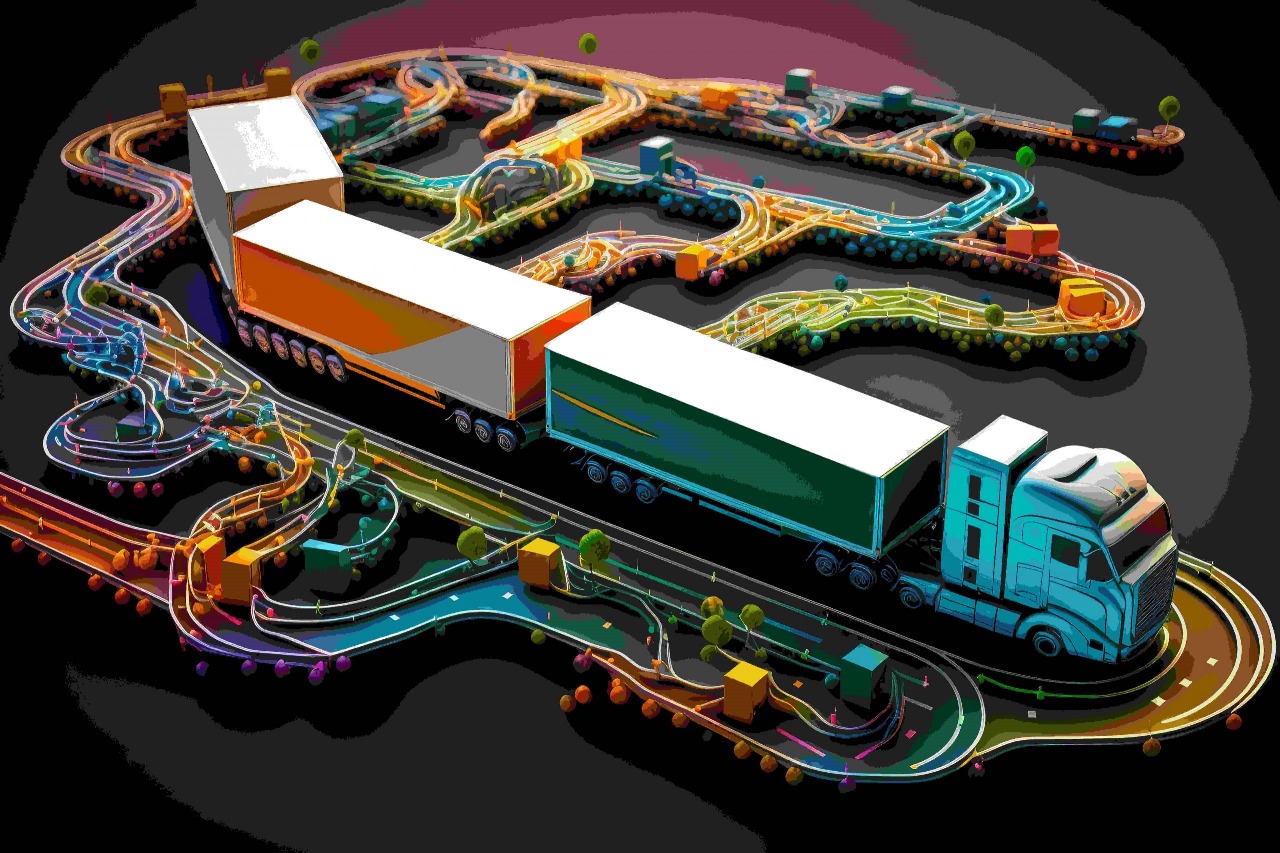

Prevent over-loading with Eagle-IoT Axle Load Monitoring

Solution to keep your fleet safe and compliant

Axle Load Monitoring

Solution

Axle Load Monitoring of heavy transport is always considered as one of the major components of Telematics. Eagle-IoT offers Axle Load Monitoring Solution to the owners of fleet of public transport,commercial vehicles and trucks, construction machines, municipal vehicles to monitor cargo transportation process in detail with the precision of 90% as instructed by the Public Transport Authority (Saudi Arabia). Whether your vehicle has a spring leaf axle or a pneumatic axle, Eagle-IoT offers a reliable solution for both.

The Eagle-IoT Advantage:

Empowering Your Journey to Wellness

Reveal Underhand Cargo

Prevent fines for exceeding load per axle and reveal underhand cargo

Loading-unloading control

Monitor loading and unloading of the vehicles to know when and where the driver loaded and unloaded the vehicle along with the valuable information about the location and time of vehicle.

Optimize Cargo Load

Use maximum capacity of vehicle.Perform big-data analysis to improve operational efficiency with fleet data

Alarm Signal

Get live notifications about actual load carried along with location.

Features

Technology:

Air Pressure Sensors

Mechanical Sensors

Strain Sensors

Fleet solutions from Eagle-IoT’s Marketplace

Asset Tracking: Gain complete visibility of assets with Eagle-IoT Asset Management. Access

reports on the utilization of high-value equipment critical to your operations

4G/ LTE Hybrid Mode of connectivity: Enjoy the benefits of dual-mode 4G/LTE+SATELITE

connectivity with Eagle-IoT to ensure uninterrupted fleet management, even when cellular

networks are unavailable.

Fuel Level Monitoring: Log your fuel consumption with Eagle-IoT to gain powerful fuel

insight and know how it contributes to asset operating costs.

Video Telematics: Take Charge of Fleet Safety with Eagle-IoT Intelligent Video Telematics

Solution Powered by AI